ISO/GMP Compliance Verification

ISO and GMP levels are also critical towards the safety and effectiveness of air showers, particularly in industries where regulations play a part such as in pharma and food industries. They offer detailed protocols for cleanroom integrity that involve the contamination of cleanrooms and clean zones. ISO and GMP-compliant manufacturers demonstrate commitment to quality and safety by producing a consistent product. These certifications validate that the operation is benchmarked against international standards and it ensures trust from customers. To verify whether the manufacturer complies with this rule, third-party auditing bodies shall be appointed by organizations to examine conformity through the following methods:(1) Systematic examination through audits. Leading companies within industries such as pharma giants often boast of being ISO and GMP certified, which is the hallmark of excellence in operational standards and safety measures.

Proven Experience in Target Industries

Air showers are required in many industries where the cleanliness is very important. The most significant sectors of the economy are health, aerospace, biotech, pharmaceuticals, and food processing. One research concentrating on cleanrooms illustrates the significance of air showers inside cleanrooms. For example, air nozzles have greatly reduced risks of contamination and have raised the standard of cleanliness in both hospitals and laboratories. Positive customer feedback from the top companies in these sectors confirm the advantages and requirements of air showers to consistently uphold very high quality standards. They have to be designed to meet your processing application requirements.Some of the signals from a manufacturer with experience would be a long standing track record in the business, numerous installations in many sectors that confirm they can meet industry specific needs.

Case Studies Demonstrating Air Shower Effectiveness

A number of case studies demonstrate the importance of air showers in maintaining clean environments and reducing the risk of contamination. For example, a pharmaceutical company said that after introducing air showers, microbial loads fell significantly and the production area was thus able to be sterilized. Another scenario in the semiconductor industry had improved operation efficiency and a reduction in defective rate due to the use of clean room air showers. A third study from a biotech lab demonstrated enhanced contamination control, which may support a sterile environment for integrity of experiments. Here are two examples that show the clear advantage of choosing the appropriate air shower for industry applications. Documented findings at respected research institutions corroborate these conclusions, proving the correlation between a well-supervised air shower and the improvement of cleanliness.

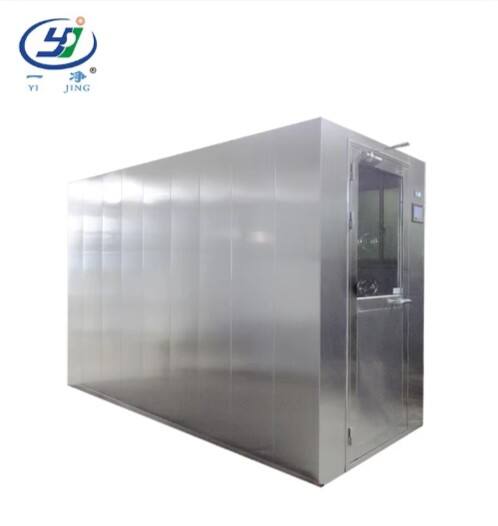

Technical Specifications for Air Shower Systems

Stainless Steel vs. Powder-Coated Steel Durability Comparison

When considering what to use for air showers, polished stainless still is frequently the preferred material for air showers in high-hygiene areas because of its hygienic qualities and durability. Stainless steel is good for applications where it is essential to minimize metallic contamination like sanitary and pharmaceutical or in the food and beverage processing, milk or other food products producing, processing, and handling applications. In addition, the tabletop is easy to wipe clean and thus very hygienic. "Powder-coated steel Is cheaper and has Anesthetic preference Its used where application is less critical and cost is major factor. For decision making purposes, test data indicates that stainless when tested against powder coated typically has a longer lifespan. Stainless steel is commonly recommended by industry experts for controlled hygiene areas, and powder-coated steel for less strict environments.

HEPA vs. ULPA Filter Efficiency in Particle Removal

Emphasizing the efficiency of filters like HEPA (High Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) is another important point of concern for air shower systems. HEPA filters capture particles as small as 0.3 microns with an average efficiency of 99.97%, which are ideal for most cleanroom applications. ULPA filters, however, are even more efficient, capturing particles as tiny as 0.12 microns at 99.999% efficiency. ULPA filters should be used for applications where the greatest degree of clean air is needed, such as laboratories used for critical research. Consider the specific compliance requirements when choosing among these filters. Filter experts generally recommend HEPA filters for general use as they represent a good trade off between cost and efficiency, but if you have those most specific tasks to accomplish, you are encouraged to install a PULPA filter. Comparing this data against the other filters shows that ULPA filters are superior, particularly in areas where smallest particle contamination can be an issue.

Air Velocity Validation Across Nozzle Designs

Air nozzle designs and air velocities produced thereby are also important to achieve sufficient particle removal and to prevent contamination when moving between clean and non-clean areas. Scrubbers These are designed to produce the airflow necessary to effectively scrub particles from surfaces with a variety of nozzles. One other reason for the need of even air flow is other work shows certain nozzle shapes can greatly improve cleaning efficiency. For example, strategically positioned high-velocity, adjustable nozzles can provide even airflow around all surfaces of the person or item to be cleaned. The performance that further demonstrate the variation between differing nozzle designs during the simulation studies indicate that additional downstream strategically placed nozzle configurations can provide increased air velocity for deeper cleaning. To adjust nozzles configurations for particular operating requirements, i.e. facility congestion and personnel throughputs, is necessary. Optimization tips include frequent nozzle calibration and targeted placement of nozzles for complete coverage and even air distribution.

Customization and Facility Integration

Modular Solutions for Space-Constrained Layouts

Modular air shower designs are extremely flexible and are a good option for facilities with space limitations. They are not inflexible systems, so that they can be inserted into a wide variety of configurations and procedures. One example of working in confined spaces are modular air showers that have been successfully used in semiconductor production without any performance penalty. But they offer great flexibility at a potential cost, complexity in retrofitting and relatively uniform performance among the various modules. There are also financial gains to balance the maintenance headache: installation time and cost can be cut by prefabricating ninja-style modular units, which are then simply bolted together on site.

Personnel vs. Material Air Shower Configuration

Civilizations and society Air showers for people and materials have special requirements which deserve careful study. Air Shower Unit for Staff Designed to decontaminate personnel entering into clean room, these often come with special features like rotating nozzles for complete washing. However, air showers are for material and are designed to decontaminate equipment or products, and can take many different forms, depending on the size and volume of the items to be treated. Safety and efficiency are two of the most heavily debated and discussed health and wellness concerns, represented by comics and memes and offering tips to keep readers out of the radiation room. In a pharmaceutical industry, e.g., a dedicated personnel air shower is effective as to a special design. Specialists call attention to important design practices concerning the need to follow patterns depending on the particular operational requirements and regulations.

Adapting Cycle Times for Workflow Efficiency

The cycle time of the air shower is an important factor to consider, as it has a direct influence on the productivity of work. Fast cycle times guarantee that decontamination maintains a high level of clean and safety, without long waits. Methods to optimize cycle lengths can involve the modification of cycle plans in accordance with traffic and operational demand. It is well documented that the agencies that are maximizing these settings are experiencing numerous improvements in workflow efficiency. Cycle time adjustments Guidelines based on cycle time adjustments can also be referenced when it is more appropriate to match for example air shower operations with the needs of the facility holding a balance between operational efficiency and requirements for high level contamination control.

Maintenance Requirements and Supplier Support

Filter Replacement Schedules and Costs

The regular maintenance of air shower system is very important, especially for filer replacement plan. Most manufactures suggest new filters be changed 6 – 12 months depending on how often the unit is run and how clean you need the room to be. Sticking to this maintenance program can add years to the life of the system, and keep it running at peak performance. The cost of different filter classes differs; e.g., HEPA filters are most often cheaper than ULPA filters, but both require proper timing concerning replacement. Prevent large failures and keep the air shower strong with routine maintenance, which can end up saving you a significant amount of money.

Accessibility for Hygiene Protocol Compliance

To prevent the non-compliance of hygiene-protocol in air shower systems, easy access for cleaning and maintenance is essential. Design features including easy to remove panels and strategically placed service points contribute to rapid and efficient maintenance, a key consideration in maintaining hygiene levels. Practical experiences have indicated that better accessibility can largely promote the system compliance in practice and the operation efficiency. Standards such as ISO and GMP typically stress the availability of easy-to- reached maintenance points to sustain systems in (normative) compliance, highlighting the latter should be taken into consideration in air shower design as well.

Service Agreements for Long-Term Reliability

Service contracts are vital to ensure the continued efficiency and effectiveness of your air showers. These can be anything from simple basic maintenance contracts to complete cover including parts and breakdown cover. With plans, you'll always have backup when problems arise, especially in times of crisis. The convenience and assurance provided by a strong service agreement is a consistent point of customer feedback, and minimizes any risk associated with equipment downtime. Thus, choosing the right manufacturer who provides good maintenance support is very important for the service life of air shower.

Comparing Reliability Through Client Feedback

Analyzing Failure Rates in High-Traffic Facilities

Air showers are a factor to consider in high volume facilities where reliability is essential to avoid production losses or maintenance costs. Research has shown that high air shower failure rates are more common and are significantly higher in heavily trafficked environments. Your hotend's performance relies on a variety of factors, some of which include frequent use, lack of proper maintenance, and not tailoring hotend settings to high throughput applications. Maintenance and robust systems to be able to handle heavy use are suggested in light of facility managers who describe reliability issues from these types of conditions. Establishing preventive maintenance protocols and utilizing empirical data including usage logs are instrumental for early identification of possible failures before reaching a critical condition whilst improving the reliability of air showers in severe environments.

Post-Installation Support Responsiveness Metrics

Prompt after service is very important service capability for This is vital to meet client’s satisfaction and it helps to running air shower in good condition. The backlogs times customers experience and the effectiveness of these resolution processes are critical to understanding supplier responsiveness. Case studies have demonstrated that this prompt assistance has an enormous effect on the effective functioning of operations, with delays often resulting in extended stoppages and the threat of contamination. Customer feedback has reinforced a preference for vendors that have in place great post-installation support programs like fast turnaround times and proactive maintenance concepts. Providing excellent support after installation help develop trust and client satisfaction into long-term relationships.

Longevity Comparisons Across Material Grades

The material grade significantly affects the life cycle of air shower system, its performance, as well as maintenance needs. Showers made of the high quality material as steel (stainless) usually reach a longer lifetime and more robustness against the climate influence. Comparative analysis shows that air showers made with high-quality materials last longer and require less frequent repairs and replacement. Knowledge on the industry indicates aiming for materials which have degrees of lifespan vs. cost, as this can offer enormous savings in continued costs. I would go with a material like stainless steel for cleanliness and longevity, but you'll want to keep it maintained as well to have it hold up long-term.

FAQ

What are ISO and GMP standards?

ISO and GMP standards are guidelines that ensure the safety and efficiency of air showers by maintaining cleanroom integrity and controlling contamination levels. They are crucial in industries such as pharmaceuticals and food processing.

Why is stainless steel preferred for air shower systems?

Stainless steel is preferred due to its exceptional durability and corrosion resistance, making it ideal for environments where hygiene and cleanliness are paramount.

How often should air shower filters be replaced?

Filters should be replaced every 6 to 12 months depending on usage intensity to ensure optimal performance and extend the system's lifespan.

Table of Contents

- ISO/GMP Compliance Verification

- Proven Experience in Target Industries

- Case Studies Demonstrating Air Shower Effectiveness

- Technical Specifications for Air Shower Systems

- Customization and Facility Integration

- Maintenance Requirements and Supplier Support

- Comparing Reliability Through Client Feedback

- FAQ