How to Choose the Right Air Handling Unit for a Clean Environment

Clean environments—such as laboratories, pharmaceutical facilities, hospitals, and electronics manufacturing plants—require precise control over air quality to protect products, processes, and people. At the heart of maintaining these controlled conditions is the air handling unit, a critical system that circulates, filters, and conditions air to meet strict cleanliness standards. Choosing the right air handling unit ensures consistent air quality, energy efficiency, and compliance with industry regulations. This guide outlines the key factors to consider when selecting an air handling unit for clean environments, from understanding cleanliness requirements to evaluating technical specifications.

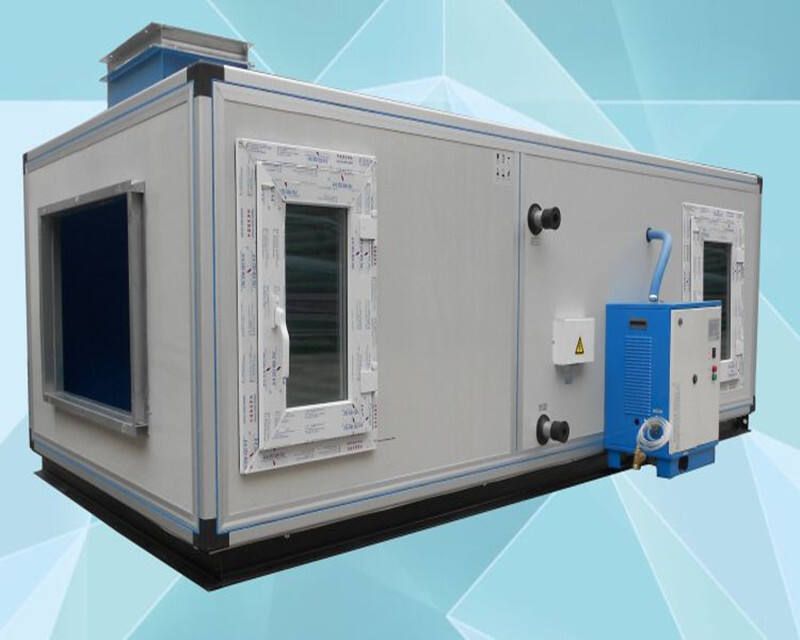

What Is an Air Handling Unit for Clean Environments?

An air handling unit (AHU) is a centralized system that regulates and circulates air within a building or specific area. In clean environments, an air handling unit goes beyond basic ventilation by incorporating advanced filtration, precise temperature and humidity control, and airflow management to minimize contaminants. These units draw in outside air, filter it, adjust its temperature and moisture content, and distribute it to the clean environment while removing stale or contaminated air.

Unlike standard air handling units used in offices or commercial buildings, those designed for clean environments prioritize:

- High-efficiency filtration to remove particles, microbes, and gases

- Strict control over airflow rates and pressure differentials

- Minimal particle generation from the unit itself

- Easy cleaning and maintenance to prevent internal contamination

- Integration with monitoring systems for continuous performance tracking

The right air handling unit acts as the backbone of a clean environment, ensuring air quality remains within specified limits (such as ISO 14644 standards) to support critical operations.

Key Factors to Consider When Choosing an Air Handling Unit

1. Cleanliness Requirements and Classification

The first step in selecting an air handling unit is to define the clean environment’s classification and contamination control needs. Clean environments are rated by standards like ISO 14644, which specifies maximum allowable particle counts (e.g., ISO 5 allows no more than 3,520 particles of 0.5μm or larger per cubic meter).

- Particle Control: For ISO 5–7 environments (e.g., pharmaceutical cleanrooms), the air handling unit must include HEPA or ULPA filters capable of removing 99.97% of particles 0.3μm or larger.

- Microbial Control: Healthcare or biological labs require an air handling unit with antimicrobial features, such as silver-ion coated filters or UV-C light integration to reduce bacteria and viruses.

- Chemical Control: Environments handling volatile organic compounds (VOCs) or corrosive gases need an air handling unit with activated carbon filters or chemical scrubbers.

The air handling unit’s filtration capacity and airflow design must align with these requirements to maintain the environment’s classification.

2. Airflow and Air Change Requirements

Clean environments depend on consistent airflow to dilute and remove contaminants. The air handling unit must deliver sufficient air volume and exchange rates:

-

Air Change Rate (ACH): This measures how many times the air in the space is replaced per hour. An air handling unit must be sized to meet the required ACH for the environment:

- ISO 5 cleanrooms: 20–60 ACH

- Hospital operating rooms: 15–25 ACH

-

Pharmaceutical compounding areas: 30–40 ACH

Calculate the required airflow by multiplying the room volume (length × width × height) by the target ACH, then select an air handling unit with matching capacity.

- Airflow Direction: The air handling unit should support the required airflow pattern. For example, unidirectional (laminar) airflow in critical zones requires an air handling unit with high-pressure fans and uniform air distribution. In containment areas, the unit must maintain negative pressure to prevent contaminated air from escaping.

- Pressure Differentials: Clean environments often require pressure gradients between zones (e.g., higher pressure in clean areas to prevent infiltration). The air handling unit must balance supply and exhaust airflow to maintain these differentials (typically 10–25 Pascals).

3. Filtration System Design

The filtration system is the most critical component of an air handling unit for clean environments. It must remove contaminants without generating new particles:

-

Filter Efficiency: Select filters based on the environment’s needs:

- Pre-filters (G3–F7) for large particles (5μm+) to protect downstream filters

- Medium filters (F8–H10) for finer particles (1–5μm)

- HEPA filters (H13–H14) for 99.97% removal of 0.3μm particles

- ULPA filters (U15–U17) for 99.999% removal of 0.12μm particles (for ultra-clean environments)

-

Filter Placement: The air handling unit should have filter banks in strategic locations, including:

- Return air filters to protect the unit from internal contamination

- Supply air filters to clean air before distribution

- Exhaust filters to treat air leaving the facility (for hazardous environments)

- Filter Access and Replacement: Choose an air handling unit with easy filter access to simplify maintenance. Features like filter pressure drop monitors help track when replacements are needed, preventing efficiency loss.

4. Temperature and Humidity Control

Stable temperature and humidity are essential for process consistency and contamination prevention. The air handling unit must provide precise control:

- Temperature Range: Most clean environments require 20–24°C (68–75°F) with tight tolerances (±1–2°C). The air handling unit’s heating and cooling coils must maintain these temperatures even with varying loads.

- Humidity Control: Relative humidity should typically be 30–60%. Too much moisture promotes microbial growth; too little causes static electricity (harmful in electronics). The air handling unit may need humidifiers (steam or ultrasonic) and dehumidifiers (desiccant or refrigeration-based) to maintain setpoints.

- Control Precision: Opt for an air handling unit with proportional-integral-derivative (PID) controllers to maintain stable conditions. Digital controls allow for precise adjustments and integration with building management systems (BMS).

5. Construction and Material Quality

The air handling unit’s construction directly impacts its performance in clean environments. Poorly designed units can generate particles or harbor contaminants:

- Internal Materials: Look for smooth, non-porous surfaces that resist corrosion and are easy to clean. Stainless steel (304 or 316 grade) is ideal for wet or corrosive environments. Avoid materials that shed particles (e.g., fiberglass insulation exposed to airflow).

- Sealing and Gaskets: The air handling unit should have airtight seals to prevent unfiltered air from bypassing filters. Gaskets made from EPDM or silicone are durable and resistant to cleaning chemicals.

- Minimized Internal Gaps: Choose an air handling unit with welded or sealed joints to prevent dust accumulation in crevices. Internal components should be streamlined to avoid airflow turbulence that can dislodge particles.

- Hygienic Design: Features like sloped drain pans (to prevent standing water), removable access panels, and stainless steel coils make cleaning easier, reducing microbial growth inside the air handling unit.

6. Energy Efficiency and Sustainability

Clean environments often require high airflow rates, making energy efficiency a key consideration for the air handling unit:

- Variable Speed Drives (VSD): Air handling units with VSD fans adjust airflow based on demand, reducing energy use during low-load periods.

- Heat Recovery: Units with heat exchangers recover energy from exhaust air to pre-condition incoming outside air, lowering heating and cooling costs.

- High-Efficiency Motors: EC (electronically commutated) motors use up to 30% less energy than standard motors and offer better speed control.

- Demand-Controlled Ventilation: The air handling unit can adjust airflow based on real-time particle counts or occupancy, optimizing energy use without compromising air quality.

While upfront costs for efficient units may be higher, long-term energy savings often justify the investment.

7. Integration and Monitoring Capabilities

A modern air handling unit should integrate with the clean environment’s monitoring and control systems:

- BMS Compatibility: The unit should connect to the building management system for centralized control, data logging, and remote monitoring.

- Sensors and Alarms: Built-in sensors for pressure, temperature, humidity, and filter status allow real-time performance tracking. Alarms notify operators of deviations (e.g., filter blockages, fan failures) to prevent downtime.

- Validation Support: For regulated industries (pharmaceuticals, healthcare), the air handling unit should provide data logs and performance reports to support compliance audits.

- Redundancy Features: Critical environments may require redundant fans, pumps, or controls in the air handling unit to prevent failures that could compromise air quality.

Types of Air Handling Units for Clean Environments

1. Packaged Air Handling Units

These compact, pre-assembled units contain all components (fans, filters, coils, controls) in a single cabinet. They are ideal for small to medium clean environments where space is limited.

- Pros: Easy installation, lower initial cost, factory-tested performance.

- Cons: Limited customization, may not meet high airflow requirements for large spaces.

2. Modular Air Handling Units

Modular units consist of separate sections (filter modules, fan modules, heating/cooling modules) that can be combined to meet specific needs. They offer more flexibility than packaged units.

- Pros: Scalable design, customizable configurations, easier to transport and install in tight spaces.

- Cons: Higher initial cost than packaged units, require professional assembly.

3. Custom-Built Air Handling Units

Designed for large or specialized clean environments, these units are engineered to meet unique requirements (e.g., ultra-high airflow, extreme temperature control, or chemical resistance).

- Pros: Tailored to exact specifications, suitable for complex clean environments.

- Cons: Higher cost, longer lead times for design and manufacturing.

4. Ceiling-Mounted Air Handling Units

Compact units installed above ceilings, ideal for cleanrooms where floor space is critical. They distribute air directly into the space with minimal ductwork.

- Pros: Saves floor space, short air distribution paths reduce pressure loss.

- Cons: Limited capacity, harder to access for maintenance.

Real-World Examples of Air Handling Unit Selection

Pharmaceutical Cleanroom (ISO 5)

A pharmaceutical manufacturer requires an air handling unit for an ISO 5 cleanroom producing sterile injectables. The selected unit features:

- ULPA filters with 99.999% efficiency

- 60 ACH airflow with unidirectional supply

- Stainless steel construction with sealed joints

- VSD fans and heat recovery for energy efficiency

- Real-time particle monitoring and BMS integration

Hospital Operating Room

A hospital needs an air handling unit for a new operating room. The chosen system includes:

- HEPA filters on both supply and exhaust

- 25 ACH with positive pressure relative to adjacent areas

- Precise temperature (22±1°C) and humidity (50±5%) control

- Antimicrobial coatings and easy-clean surfaces

- Redundant fans to ensure continuous operation

Electronics Manufacturing Facility

An electronics plant requires an air handling unit for an ISO 6 cleanroom producing microchips. The unit has:

- ULPA filtration to remove sub-micron particles

- Low-static airflow design to prevent electrostatic discharge

- Desiccant dehumidification to maintain 30–40% humidity

- Energy recovery from exhaust air

- Filter pressure monitoring with automatic alerts

FAQ

What size air handling unit do I need for my clean environment?

Calculate the required airflow by multiplying the room volume (m³) by the target air change rate (ACH). For example, a 100 m³ room requiring 30 ACH needs an air handling unit with 3,000 m³/h airflow capacity. Always size for 10–15% extra capacity to account for filter loading and future needs.

How often should filters in an air handling unit be replaced?

Pre-filters: every 1–3 months.

Medium filters: every 6–12 months.

HEPA/ULPA filters: every 1–3 years, depending on usage.

Monitor pressure drop across filters—replace when pressure increases by 50% above initial levels.

Medium filters: every 6–12 months.

HEPA/ULPA filters: every 1–3 years, depending on usage.

Monitor pressure drop across filters—replace when pressure increases by 50% above initial levels.

What’s the difference between an air handling unit for clean environments vs. standard buildings?

Clean environment air handling units have higher-efficiency filtration (HEPA/ULPA), tighter control over temperature/humidity, airflow direction management, and hygienic construction to prevent particle generation. Standard units focus on comfort rather than contamination control.

Can an air handling unit be retrofitted to improve clean environment performance?

Yes, retrofits can include upgrading filters to HEPA/ULPA, adding VSD fans for better control, installing humidity controls, or integrating monitoring sensors. However, major upgrades may be less cost-effective than replacing an outdated unit.

How important is energy efficiency for an air handling unit in a clean environment?

Very important. Clean environments often require high airflow rates, making air handling units energy-intensive. Efficient units with VSD, heat recovery, and demand control can reduce energy costs by 20–40% while maintaining air quality.

Table of Contents

- How to Choose the Right Air Handling Unit for a Clean Environment

- What Is an Air Handling Unit for Clean Environments?

- Key Factors to Consider When Choosing an Air Handling Unit

- Types of Air Handling Units for Clean Environments

- Real-World Examples of Air Handling Unit Selection

-

FAQ

- What size air handling unit do I need for my clean environment?

- How often should filters in an air handling unit be replaced?

- What’s the difference between an air handling unit for clean environments vs. standard buildings?

- Can an air handling unit be retrofitted to improve clean environment performance?

- How important is energy efficiency for an air handling unit in a clean environment?