Understanding Modular Clean Rooms

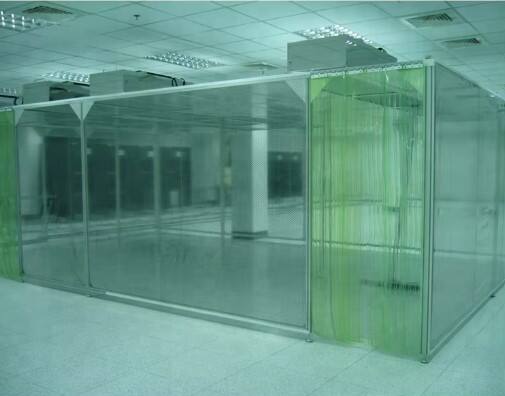

Modular clean rooms create controlled spaces where dust and particles are kept at bay, something really important for places like drug manufacturing plants, semiconductor factories, and research labs working with sensitive biological materials. The whole setup comes in pre-made sections that just snap together when they arrive on site, which means companies get their facilities up and running much quicker than traditional builds. Plus these modular designs let businesses tweak or grow their clean room space as needed without major disruptions. Many hospitals and tech firms have switched to this approach because it saves time during installation and adapts better to changing production demands over time.

Modular clean rooms are important because they cut down on contamination without breaking industry rules. Industry data shows these rooms can slash particulates by as much as 90%, which really helps keep products safe and pure when made in places where dirt matters a lot. For pharma companies especially, this kind of control makes all the difference since tiny bits of impurity might actually ruin how well medicines work. What makes modular setups so good is that they fit different needs easily and still perform reliably. That's why many manufacturers rely on them day after day to protect what goes into those critical production lines.

Benefits of Modular Clean Room Construction

Building modular clean rooms can save companies a lot of money, with some research pointing to around 30% less spending than old school construction techniques. The main reason? Prefab parts that cut down on time spent building and throw away way less material during setup. Industry folks have noted that this kind of saving really helps small operations or startups watching their bottom line closely. Instead of bleeding cash on infrastructure, they can invest those funds elsewhere where they might actually grow the business instead of just maintaining facilities.

Getting things up and running faster is one big plus when it comes to building modular clean rooms. Since most parts come pre-made from the factory, putting them together at the site takes way less time than traditional methods. We're talking about cutting down installation periods by weeks sometimes. That speed really helps keep projects moving along while causing minimal hassle for whatever work is already happening nearby. Take pharma companies or semiconductor manufacturers for instance. These businesses often need sterile spaces brought online fast to stay competitive. Being able to hit those tight deadlines makes all the difference in maintaining production schedules and meeting regulatory requirements without unnecessary delays.

Modular designs bring built-in flexibility, making it much easier to expand or reconfigure spaces as industry requirements shift over time. Many manufacturing firms need clean rooms that can actually grow alongside their business rather than becoming obsolete when demand increases. Take for instance what happened at one facility studied by G CON Manufacturing last year. They managed to add an entire new production line to their existing modular clean room setup during regular business hours, avoiding weeks of costly shutdowns that would have been necessary with traditional construction methods. Facilities stay up to date with regulations while also being able to adopt emerging technologies faster than competitors stuck with rigid infrastructure. The real value comes from not having to completely rebuild whenever scaling operations becomes necessary something that saves both money and headaches across different sectors from pharmaceuticals to food processing.

Key Features of Modular Clean Rooms

Modular clean rooms come with sophisticated filtration setups like HEPA and ULPA filters, and these components really matter when it comes to controlling airborne contaminants. The filtration systems need to comply with ISO 14644 guidelines, which basically set the bar for how clean the air needs to be inside these controlled environments. Speaking of specifics, standard HEPA filters will catch most particles down to about 0.3 microns in size. But if extra protection is needed, ULPA filters take things further by trapping around 99.999% of particles measuring 0.12 microns or bigger. This kind of performance makes them ideal for applications where even the tiniest specks could cause problems.

When building modular clean rooms, picking the right materials matters a lot for keeping things hygienic and making maintenance easier down the road. Most manufacturers point towards non-porous options since these satisfy those tough cleanliness requirements everyone in the business has to follow. The good news is these kinds of surfaces just wipe down nicely, which cuts down on contamination problems and keeps facilities within regulatory boundaries. Stainless steel remains a top pick among professionals, alongside HDPE plastics too. Both stand up well against bacteria buildup and resist damage from harsh chemicals commonly used in cleaning processes.

Modular clean rooms really shine when it comes to customization options. These spaces can actually be built to fit whatever specific processes or workflow requirements a business might have. The flexibility aspect means businesses get better use out of their available space while making sure all the necessary processes fit together properly. Take pharmaceutical manufacturing for example. Many drug makers need separate areas for various parts of their production line. With modular systems, these different zones just snap together like puzzle pieces. Looking at real world applications, we've seen plenty of facilities where switching from traditional construction to modular setups allowed them to grow operations without tearing everything down. Some even managed to stay compliant with new regulations simply by rearranging modules instead of doing expensive renovations.

ISO Classifications and Their Relevance

ISO standards for clean rooms, especially ISO 14644-1, set the framework for classifying these environments according to their maximum particle count allowances. The classification system runs from ISO Class 1 all the way up to ISO Class 9, where each category defines strict limits on airborne particulate concentrations. Take ISO Class 5 as an example it permits a maximum of around 3,500 particles measuring 0.5 microns or bigger within one cubic meter of air. Compare that to ISO Class 7 which tolerates approximately 350 thousand particles at the same size range. These differences matter because they guide manufacturers and researchers when deciding what level of environmental control their particular processes actually require.

The ISO classification system plays a big role when designing clean rooms, affecting everything from how many times per hour the air gets changed to how the space is laid out and what materials get used. Rooms with higher ISO ratings typically need more frequent air changes just to keep up with the required cleanliness levels. When it comes to layout, proper airflow patterns are absolutely critical to stop contaminants from spreading around. Most designers go for materials that don't trap particles either, so non-porous surfaces become the norm rather than the exception. The smart approach is to think about these ISO requirements right at the beginning of any project planning. Getting this right from day one helps manufacturers hit their cleanliness targets without wasting money on unnecessary upgrades down the road.

Navigating Challenges in Modular Clean Room Projects

Many modular clean room installations run into major headaches along the way. Compliance with regulations and fitting these systems into older buildings tend to be big problems, something many different industries have struggled with over time. Research suggests around 60 percent of such projects face delays because they need to meet so many strict rules, which naturally affects both money spent and project schedules. When trying to install these clean rooms inside existing facilities, there's always the challenge of making everything fit together properly. This requires careful planning and coordination between technical teams and logistics staff to make sure nothing goes wrong during installation.

There are definitely some key approaches needed to handle these kinds of problems. Good old fashioned planning before starting anything at all helps catch those pesky compliance headaches and makes sure everything will actually work with what's already there. Getting people who matter involved from day one really pays off too. When clients, suppliers, and local authorities know what's going on upfront, everyone tends to cooperate better and things just run more smoothly overall. And let's face it, bringing aboard folks who have seen similar projects through from start to finish makes a world of difference. These pros spot trouble spots most others miss, which means fewer surprises down the road. That kind of expertise keeps projects moving forward instead of getting stuck in endless problem solving mode.

Getting expert project management right makes all the difference when it comes to finishing projects on time and under budget. Take Porta-King's work with Atrium Innovations and U.S. Customs as prime examples of this. These weren't just random successes but rather carefully planned operations where everything from risk assessment to staff scheduling was handled properly. What stands out most about these cases is how they managed unexpected problems without blowing past deadlines or going over budget. The real secret sauce? Seasoned leaders who knew exactly when to push forward and when to hold back. Their experience kept things on track even when challenges arose, which ultimately led to results that met or exceeded expectations across the board.

Future Trends in Modular Clean Room Technology

Modular clean room tech is evolving fast thanks to some pretty cool innovations and increasing focus on sustainability issues. One big change we're seeing now involves real time monitoring systems working alongside automated processes. New sensors can track things like moisture levels and dust particles constantly throughout the facility. Clean room operators are starting to adopt robotic systems for moving materials around too, which makes operations run smoother while cutting down on mistakes made by people. What's happening here goes beyond simple improvements though it's actually raising the bar for what counts as precise manufacturing these days. Companies that embrace these changes find themselves ahead of competitors when it comes to both quality control and bottom line savings.

Environmental concerns are now playing a major role in how clean rooms get designed alongside all the tech improvements we see. More companies are going for energy saving approaches and using materials that won't harm the planet, something backed up by recent market data. According to research from ISPE, switching to greener methods can cut down running expenses anywhere between twenty to thirty percent. Going green isn't just good PR anymore it's actually required by many regulations these days regarding carbon emissions. Looking ahead, those firms that manage to combine cutting edge technology with real sustainability efforts stand out in this competitive market landscape.

FAQ

What are modular clean rooms?

Modular clean rooms are specialized environments constructed using prefabricated modules, designed to maintain strict particulate contamination control, essential for industries like pharmaceuticals and electronics.

How do modular clean rooms benefit industries?

They offer cost-effectiveness, time efficiency, and flexibility, allowing quick assembly, reduced installation times, and easy expansion or reconfiguration to meet specific industry needs and standards.

What is the importance of ISO classifications in clean rooms?

ISO classifications determine the cleanliness level required for various applications, influencing design decisions such as air change rates, layout, and material selection.

What challenges might arise in modular clean room projects?

Common challenges include regulatory compliance and integration with existing facilities, which can impact timelines and budgets if not properly addressed with effective strategies and project management.