Comprensione degli ambienti di cleanroom

Le cleanroom rappresentano spazi controllati progettati specificatamente per mantenere al minimo la contaminazione preservando standard estremi di pulizia. Si trovano ovunque, dagli impianti di produzione ai laboratori farmaceutici e ai centri di ricerca scientifica, dove la qualità del prodotto non può assolutamente tollerare impurità. Cosa rende così efficaci queste stanze? Il loro design si concentra sul controllo delle contaminazioni aerodisperse, come particelle di polvere, batteri e minuscoli aerosol, che potrebbero altrimenti compromettere processi delicati o la qualità finale dei prodotti. Per settori che trattano microelettronica, dispositivi medici o materiali biologici sensibili, questo livello di controllo ambientale non è soltanto utile, ma assolutamente necessario per rispettare le rigorose normative industriali.

Il funzionamento delle cleanroom è molto importante perché la loro efficienza influisce su tutto, dalla qualità del prodotto ai costi operativi e al rispetto delle normative. Prendiamo ad esempio gli standard ISO 14644, che definiscono i requisiti necessari affinché le cleanroom mantengano un livello di pulizia adeguato ai processi produttivi. Quando le aziende seguono queste linee guida, garantiscono che le loro strutture rimangano pulite nel modo corretto ed operino in modo efficiente. Dal momento che l'efficacia delle cleanroom è direttamente collegata al corretto funzionamento dei prodotti e al rispetto delle normative, le aziende non possono permettersi di trascurare questi aspetti. Un singolo errore nella manutenzione può causare interruzioni della produzione che costano migliaia di euro o addirittura sanzioni per non aver seguito correttamente le regole.

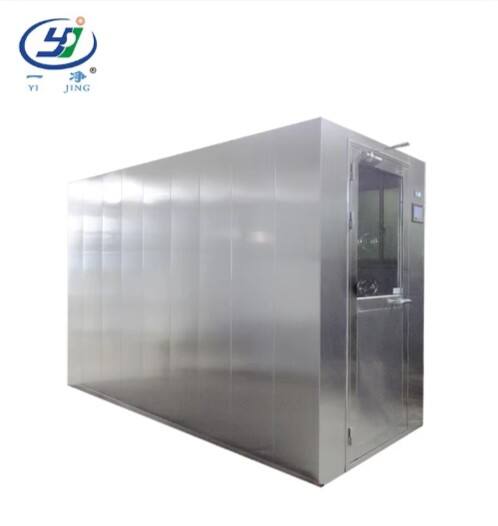

Come Docce d'aria Operare

Le docce d'aria svolgono un ruolo fondamentale nel mantenere le camere pulite prive di particelle e detriti indesiderati. Quando le persone entrano in queste aree sensibili, portano con sé varie contaminazioni su vestiti e pelle. È qui che entrano in gioco le docce d'aria. Esse emettono aria filtrata HEPA a elevata velocità per rimuovere polvere, capelli e altre particelle microscopiche prima che qualcuno entri. La maggior parte dei sistemi moderni è dotata di sensori di movimento che si attivano automaticamente quando qualcuno passa attraverso. La forza dell'aria fondamentalmente elimina qualsiasi cosa possa essere rimasta attaccata a giacche, scarpe o guanti. Questo semplice ma efficace processo aiuta a mantenere le condizioni estremamente pulite necessarie, ad esempio, per la produzione di farmaci o la ricerca di laboratorio, dove anche minuscole particelle possono rovinare interi lotti. Senza adeguati sistemi di docce d'aria, molte strutture avrebbero difficoltà a rispettare gli elevati standard di controllo delle contaminazioni.

Diverse componenti importanti collaborano per rendere efficaci le docce d'aria nella rimozione di contaminanti. I filtri HEPA svolgono un ruolo fondamentale catturando polvere, sporco e altre particelle minuscole mentre le persone passano attraverso la camera. La maggior parte delle unità moderne è dotata di sistemi di circolazione dell'aria che spingono aria pulita attraverso ugelli posizionati tutto intorno all'abitacolo, a volte persino all'altezza della testa dove tende ad accumularsi la contaminazione. Pannelli di controllo con microprocessori integrati gestiscono quando e quanto intensamente l'aria deve soffiare, regolandosi in base a chi entra e da quale tipo di ambiente proviene. Tutte queste caratteristiche combinate aiutano a mantenere prestazioni costanti in diversi ambienti, assicurando che le strutture rimangano pulite senza richiedere continuamente aggiustamenti manuali.

Esaminando i vari modi per controllare la contaminazione, gli air shower si distinguono come soluzione particolare. Le stanze per la vestizione aiutano le persone a prepararsi, ma onestamente non sono sufficienti quando si tratta di particelle minuscole che non riusciamo nemmeno a vedere. I tappetini adesivi posizionati all'ingresso funzionano abbastanza bene per le scarpe, ma riescono a catturare soltanto una certa quantità di sporco e polvere. Gli air shower vanno effettivamente oltre queste alternative, poiché rimuovono le contaminazioni da ogni parte del corpo prima di entrare nell'area pulita. Per questo motivo molte aziende farmaceutiche e produttori di semiconduttori fanno ampio affidamento su di essi. Dopotutto, mantenere un livello di pulizia estremo è fondamentale in questi settori, dove anche la più piccola particella potrebbe rovinare migliaia di dollari di prodotto.

Come Docce d'aria Migliora Camera pulita Efficienza

Le camere di decontaminazione ad aria migliorano davvero l'efficacia delle cleanroom, poiché riducono notevolmente la contaminazione. Quando si lavora in questi ambienti estremamente puliti, anche piccolissime quantità di sporco o polvere possono causare problemi gravi e fermi prolungati, che incidono negativamente sui livelli produttivi generali. Queste camere utilizzano potenti getti d'aria per rimuovere ogni tipo di particella dagli indumenti e dall'equipaggiamento dei lavoratori mentre entrano ed escono dalle aree sensibili. Ciò che le rende preziose è la capacità di impedire che i contaminanti raggiungano i processi critici, consentendo al contempo al personale di tornare rapidamente alle proprie attività senza dover attendere interventi di pulizia. La maggior parte delle strutture segnala miglioramenti evidenti sia nella qualità dei prodotti che nella continuità operativa dopo l'installazione di adeguati sistemi di camere di decontaminazione.

Per ottenere il massimo dagli air shower dipende davvero dall'implementazione di buone routine di pulizia e protocolli adeguati. La maggior parte degli esperti del settore consiglia di integrare l'utilizzo degli air shower direttamente nei piani standard di manutenzione delle cleanroom, in modo da mantenere sempre tutto impeccabilmente pulito. Un tipico protocollo prevede l'esecuzione di cicli specifici di air shower per ogni persona in entrata o in uscita, oltre a ispezionare regolarmente filtri e ugelli per assicurarsi che funzionino correttamente. Queste pratiche quotidiane mantengono gli air shower al massimo delle prestazioni e proteggono l'intero ambiente della cleanroom dai rischi di contaminazione. Le strutture che adottano questo tipo di misure solitamente riscontrano meno problemi di qualità nel lungo termine.

Le valutazioni sull'efficienza delle docce d'aria sono molto importanti per capire quanto effettivamente funzionino bene. Molto spesso, questi parametri tengono conto di aspetti come la velocità del flusso d'aria (generalmente espressa in metri al secondo) e quante volte all'ora l'aria viene completamente sostituita all'interno della camera. In generale, un'aria in movimento più veloce e sostituzioni più frequenti significano un migliore controllo dei contaminanti che entrano in aree sensibili. Per chi gestisce stanze pulite, conoscere questi valori aiuta a scegliere le docce d'aria più adatte alle esigenze della struttura per mantenere gli standard di pulizia richiesti durante le operazioni quotidiane.

Vantaggi dell'uso Docce d'aria

Installare docce d'aria nelle cleanroom alla fine conviene, perché riduce notevolmente i costi legati alla contaminazione che possono incidere sui bilanci. Sebbene richieda una spesa iniziale per l'installazione, la maggior parte delle strutture scopre che il portafoglio rimane più solido dopo l'installazione, visto che i difetti dei prodotti diminuiscono in modo significativo e il personale addetto alle pulizie non deve sforzarsi troppo per mantenere tutto impeccabilmente pulito. Il vero vantaggio sta nel fatto che questi sistemi tengono lontane le particelle di polvere dalle aree sensibili, il che significa che le unità HVAC non devono lavorare straordinari per compensare l'accumulo costante di sporco. Anche i filtri durano più a lungo, quindi gli intervalli di sostituzione si allungano e le spese di manutenzione si riducono mese dopo mese.

Le docce d'aria in realtà aiutano a risparmiare denaro nel lungo termine perché mantengono puliti gli ambienti e il loro equipaggiamento in condizioni migliori. Questi sistemi riducono l'usura normale che si verifica in questi ambienti controllati, facendo sì che tutto duri più a lungo prima di dover essere sostituito o riparato. Le strutture che installano le docce d'aria tendono ad incontrare meno problemi causati dall'ingresso di contaminanti in aree sensibili. Questo significa meno tempo perso per fermare le operazioni per pulizie o riparazioni. Per industrie in cui anche le particelle più piccole possono rovinare i prodotti, come nella produzione di farmaci o nella fabbricazione di semiconduttori, questo tipo di affidabilità fa la differenza tra un funzionamento regolare e costosi ritardi.

Dal punto di vista psicologico, seguire protocolli per ambienti puliti, come le docce d'aria, aumenta notevolmente il morale e la fiducia dei dipendenti. Quando i lavoratori vedono questi procedimenti in azione, iniziano a comprendere quanto sia fondamentale mantenere un ambiente sicuro e sterile. La maggior parte delle persone si sente meglio sul lavoro quando sa che vengono adottate le giuste misure per garantire un ambiente privo di contaminazioni. L'attenzione per la pulizia crea un senso di responsabilità condivisa tra i membri dello staff. I team tendono a collaborare in modo più efficace perché tutti sono allineati riguardo a ciò che deve essere fatto. Questo tipo di cooperazione si traduce direttamente in tassi di produttività migliori e in un output di qualità più elevata in tutti i tipi di ambienti produttivi controllati.

Settori che traggono beneficio dalle cabine d'aria

Per le industrie che tengono davvero alla pulizia, come le aziende farmaceutiche e i laboratori biotecnologici, le docce d'aria sono molto importanti. Questi ambienti devono rispettare regole molto rigorose per il controllo dei contaminanti. Le docce d'aria agiscono sostanzialmente come una sentinella, impedendo alle minuscole particelle di entrare nelle aree dove vengono prodotti i farmaci. Questo fa tutta la differenza per garantire che i medicinali rimangano sicuri e puri. Pensate in questo modo: se anche una minima particella di polvere entra in un lotto di farmaci durante la produzione, potrebbe rendere l'intero lotto inutilizzabile o, peggio ancora, causare problemi di salute ai pazienti. Considerando esclusivamente le implicazioni sui costi, le docce d'aria valgono davvero tanto per i produttori che non possono permettersi richiami o sanzioni regolamentari lungo il processo.

I settori della microelettronica e dell'aerospaziale affrontano problemi seri di contaminazione, motivo per cui le docce d'aria sono così cruciali. Si pensi ai microchip, dove particelle di polvere di soli pochi micron possono compromettere completamente il funzionamento dei circuiti. Per quanto riguarda i componenti aeronautici, sporco e detriti non sono soltanto un fastidio: rappresentano effettivamente un rischio reale per la sicurezza e per il corretto funzionamento sotto stress. È in questo contesto che entrano in gioco le docce d'aria come prima barriera contro i contaminanti. Questi sistemi aiutano a mantenere pulite le aree di produzione così come richiesto da rigorosi standard qualitativi, garantendo operazioni affidabili giorno dopo giorno.

I laboratori di ricerca e le strutture scientifiche ottengono un valore reale dall'utilizzo delle docce d'aria nelle loro operazioni. Molti laboratori lavorano su esperimenti delicati in cui piccole quantità di polvere o particelle possono compromettere interi studi e rovinare mesi di lavoro. L'installazione di docce d'aria aiuta a mantenere questi ambienti puliti e controllati, assicurando ai ricercatori dati precisi e affidabili. Tenere lontani i contaminanti fa tutta la differenza quando si effettuano esperimenti corretti. Senza questa protezione, fattori esterni potrebbero alterare i risultati, rendendo più difficile per gli scienziati ottenere scoperte o pubblicare risultati affidabili che resistano alla verifica.

Migliori pratiche per l'implementazione delle cabine aerodinamiche

Per far funzionare bene le docce d'aria, è importante considerare alcuni aspetti essenziali. La formazione adeguata del personale rimane uno dei fattori più importanti. Quando le persone conoscono esattamente il modo corretto di utilizzare questi sistemi, si ottiene una grande differenza nel farli funzionare come previsto, mantenendo l'intera cleanroom operativa in modo efficiente. È preferibile integrare le docce d'aria fin dalle prime fasi di progettazione della cleanroom, piuttosto che aggiungerle successivamente. Posizionarle strategicamente può migliorare davvero il movimento dei materiali all'interno dello spazio e ridurre la quantità di particelle indesiderate che entrano nelle aree sensibili. Anche la manutenzione non viene discussa abbastanza. Verifiche regolari e aggiornamenti necessari mantengono questi sistemi sempre al top delle prestazioni. Una doccia d'aria ben mantenuta dura più a lungo e continua a proteggere la qualità del prodotto da contaminazioni che potrebbero compromettere tutte le altre operazioni all'interno dell'impianto.

Domande Frequenti

Qual è lo scopo di una sala pulita?

Una sala pulita è progettata per minimizzare la contaminazione e mantenere un ambiente controllato, essenziale per industrie ad alta precisione come quelle farmaceutiche e manifatturiere.

Come contribuiscono le docce aeree all'efficienza della sala pulita?

Le cabine di decontaminazione a getto d'aria utilizzano getti d'aria ad alta velocità per rimuovere i contaminanti dal personale e dagli equipaggiamenti, riducendo i rischi di contaminazione e migliorando l'efficienza delle aree pulite.

Quali settori traggono maggior vantaggio dagli air shower?

Settori come quelli farmaceutico, biotecnologico, microelettronico, aerospaziale e strutture di ricerca traggono grande beneficio dal controllo della contaminazione offerto dalle cabine di decontaminazione a getto d'aria.