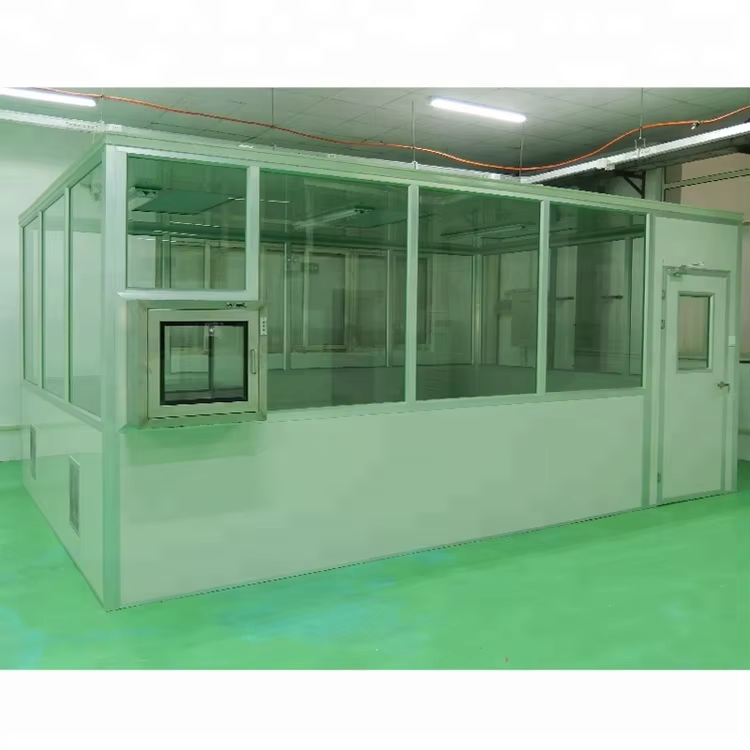

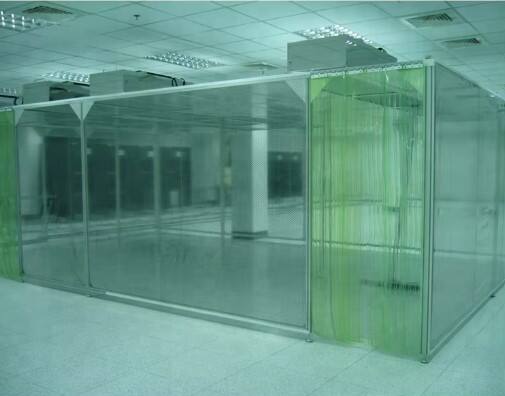

Күрүлгөн ISO жана GMP стандарттары Модулдуу таза бөлмөлөр

ISO 14644 классификация системасы

Таза бөлмөлөрдү классификациялоонун бир маанилүү стандарты ISO 14644 болуп саналат. Таза бөлмөдөгү тазалыкты классификациялоо аба көлөмүндө 0,5 мкм жана андан чоң болгон бөлүкчөлөрдүн саны менен чектелет. Бул серияны Халык аралык стандартташтыруу уюму түзгөн, эң катуу стандарт болгон ISO Класстын 1синен тартып ISO Класс 9 чейин таза бөлмөлөрдү классификациялайт. Класстардын бөлүкчөлөрдүн рүксат берилген өлчөмүнө, мисалы, 0,1 мкм жана андан чоң жана ар бир м3 тутумда каншалык концентрация болушуна негизделет. Дарылар же таза бөлмөлөрдү иштетүү үчүн бул категорияларды сактоо маанилүү, анткени аларга тийешелүү тазалык деңгээли зарыл. Тийиштүү тесттер менен мониторинг жүргүзүлүп, алдын ала белгиленген түрлөрдөн кандайдыр бир айырмачылыктар аныкталат.

Модульдүү Таза бөлмө ISO стандарттарына ылайыктыкты камсыз кылуу үчүн модулдук таза бөлмөлөрдү белгилүү бир ыкмалар менен сыноо жана текшерүү керек. Бул ишке аба чисталыгын, аба агымынын ылдамдыгын жана басым айырмасын көзөмөлдөө кирет, бул көрсөткүчтөр ISO класстарынын деңгээлин аныкташта маанилүү роль ойнойт. Бирок ылайыктуулук бир жолку иш эмес, ал ISO 14644 стандартында көрсөтүлгөн тийиштүү айлана-чөйрө шарттарына ылайык регулярдык аудит жана өзгөртүүлөргө уланып турган милдет. Модулдук тез тарбиялоого жана көбүнчө тез колдонууга мүмкүнчүлүк берген таза бөлмөлөр үчүн ISO 14644 стандартынын талаптарына ылайык болуу – бул ар түрдүү өнөр жайда сезгич өнүмдөрдү өндүрүү үчүн баш керек шарт.

EU GMP Кошумча 1 Талаптары

Инфекциялар жана булгундоштуруу Brexit ЕМАнын кайра каралган 1 кошумчасы: нускамалардын талаштуу бөлүмү боюнча туура ачыктыкка жетүү ЕМАнын 1 кошумчасынын соңку өнүгүшү стерилдүү өнімдөрдү, фармацевтикалык өнімдөрдү жана жаны бар организмдер менен иштөөчүлөрдү өндүрүүдө чоң мааниге ээ. Таза бөлмөлөрдү куруу, колдоо жана иштетүү талаптары контейнерге каршы күрөш жана табигый ортону байкоо боюнча атайын көңүл бөрүлөт. 1 кошумчанын A-дан D-га чейинки деңгээлдери микробдук булгундоштуруу жана тейлөө деңгээлин эсепке алуу менен ISO 5-тен 8 класска жакын келет. Булгундоштурууну башкаруу стратегиясы (CCS) жана изолятор сыяктуу технологиялык барьерлерге байланышкан стратегиялар кызматкерлердин аралашуусун азайтууга багытталган.

Бул стандарттардын модулдук таза бөлмөлөргө маанилүү жана көп жагынан маанилүү экени айкын. Бул өзгөчө дарылар өнөмдүрүлгөн жерде ыңшыктык талап кылынат. Модулдук таза бөлмөлөр - катуу талаптарга жооп бере турган жөнгө салууга болгон жана ылдам чечим: Өзүнүн катуу стандарттары менен таза бөлмөлөр коопсуздукту жана дарылардын сапатын камсыздаш үчүн зарыл. Статистикалык маалыматтар Аннекс 1 шарттарына жооп берүү бөлмөдөгү лабораториялык жабырткылардын таасирин кемитип, дарылардын сапатын жана иштетүү сапатын арттырышын көрсөткөн. Европа биримдигинин бозарына экспорттоо же аралашуу үчүн уюмдар бул талаптарга жооп бериши керек жана модулдук чечимдер жогорку сапаттагы талаптарга жетүүнүн оңой жолу болуп саналат.

USP <797> жана <800> ыңшыктык

USP <797> жана <800> стандарттары стерилдүү жана курч дарыларды (колдонуучуга зыян келтириши мүмкүн дарыларды) даярдоо үчүн жана АКШдагы таза бөлмөлөрдүн шарттары үчүн катуу талаптарды түзүлгөн. USP <797> стерилдүү даярдоону параметрлештирет; башкача айтканда, тазалоо протоколдору, персоналдын өзгөчөлүктөрү жана иштөө шарттары (мисалы, аба тазалыгы жана басым айырмасы) ISO Class 5 жана Class 7 критерийлери менен ылайык келген биринчи инженердик контролдор үчүн, ошондой эле кошумча тейлөөчү орто чөйрөлөр үчүн белгиленген. USP <800> бул маселелерге жанаша келет, курч дарылар менен иштөөнү талап кылат жана операторлорду жана дары сапатын коргоо үчүн терс басым контролдору жана чыгаруу системалары болушу керктигин талап кылат.

Модулдук таза бөлмөлөрдү иштетүүнүн эң жакшы тәжрыйбесине ылайык, мисалы, бир жактуу аба агымы, аймак стратегиясы жана мониторингди колдоо үчүн иштетүүнүн эң жакшы тәжрыйбесине ылайык эркен мүмкүнчүлүктөрдү колдонуу менен ушул шарттарга ылайык куруу керек. Бул стандарттарга ылайык келүүнүн бир гана мүмкүн болгон вариант - басымдык каскаддык системалар жана камоо технологияларын орнотуу. Ошондой эле, эң жакшы тәжрыйбенин ичине ыңгайлаштырылган кийим жана материал өткөрүү аймактары кирет, ал таза модулдук бөлмөлөрдүн USP <797> жана <800> талаптары менен бирге иштөө мүмкүнчүлүгүн арттыруу үчүн долбоорлонгон. Бул эң жакшы тәжрыйбелер модулдук таза бөлмөлөрдүн орнотулган учурда гана эмес, ошондой эле орнотулгандан кийин да стандарттарга ылайык келүүсүн камсыз кылат, бул сертификаттоо үчүн маанилүү.

HVAC Дизайн Принциптери Бөлүктерин Башкаруу Үчүн

Аба Агымынын ылдамдыгы жана Багыт Стандарттары

Clenrent™: Таза бөлмөнүн бүтүндүгүн сактоо Аба агымынын ылдамдыгы менен багыттарын түшүнүү маанилүү. Аба менен таралган патогендерди бөлмөдөн каншалык дәрээжеде басуу жана чыгаруу аба агымынын ылдамдыгы менен багыты таасир этет. Аба агымынын багытын сактап, ластоонун ыктымалдуулугун азайтуу үчүн HVAC системаларын долбоорлоо керек. Негизги долбоордо эң жакшы тәжрибелердин бири – бир багыттуу ламинардык агымды колдонуу жана аба берүү менен кайтаруу решеткаларын орнотуу. Аба агымын башкаруу жана басым туннелдеши Аба агымын башкарууну сактоо ластоонун деңгээлинин маанилүү азайышына алып келет, таза бөлмөнүн эффективдүүлүгүндө анын ролүн баса белгилейт.

HEPA/ULPA Сүзгүч системалары

HEPA жана ULPA фильтрлери чөп чап көрүнбөгөн бөлмөлөрдөгү майда бөлүкчөлөрдү топтоо үчүн зарыл. HEPA (High Efficiency Particulate Air) фильтрлери 0,3 микрон өлчөмүндөгү бөлүкчөлөрдү 99,97% эффективдүүлүк менен кармап алса, ULPA (Ultra Low Penetration Air) фильтрлери дагы кичине бөлүкчөлөрдү жакшы кармап, тазалыкты көбөйтөт. Бул фильтрлөө системаларын оптималдуу иштетүү үчүн техникалык күтүм көрсөтүү жана алмаштыруу графиктерин сактоо маанилүү. Тазалоочу системаларды колдонуу менен загрязнениени 99% чейин камтыйт. Тазалоочу системаларды эффективдүү колдонуу загрязнениени күрсөтүүнү камтыйт жана чистый бөлмөнүн иштешин жакшыртат.

Басымдык айырманы сактоо

Эң маанилүүсү, модулдуу таза бөлмөдө киргизүү жолдорун башкарууда басымдын түшүшүн камсыз кылуу керек. Эгерде эс алуу таза бөлмөдөн сыртка чыгып жатса, сырткы кирди киргизбөө үчүн оң басым аба чыгып жатат, ал эми терс басым кээ бир куркунучтуу дарыларды колдонуу үчүн «көмүр» кирди аба тутуп алат. Түрдүү таза бөлмөлөрдүн бөлүмдөрүндө басымды башкаруу жана сактоо үчүн интеллектуалдуу датчиктер системасы жана автоматтандыруу башкаруу колдонулушу мүмкүн. Басымдын тиимдүү башкарылышы таза бөлмөнүн жалпы эффективдүүлүгүн арттырат жана катуу стандарттарга ылайык келет.

Материал жана курулуш техникалык шарттары

Жарым-жартылай бет бетинин талаптары

Таза бөлме шарттарында эриксиз беттердин мааниси чоң. Эриксиз материалдар деген эмне? Эриксиз материалдар - бул суюк же аба өткөрбөй турган жана суу менен деле киргизилбейт. Шыны, металл жана катуу пластмассалар сыяктуу материалдар эриксиз. Микроорганизмдер үчүн эриксиз беттерге кирүү кыйын, бул бактериялык жана саңыраак өсүшүнүн коркунучун төмөндөтөт. Стерилизация кылууга жеңил материалдарды тандаш керек, модулдук таза бөлмелерди курууда бул өтө маанилүү. Коррозияга төзүмдүү материалдар сыяктуу эле нержат болот жана шыны же определенный пластмассалар терс алынат. Статистикалык маалыматтарда ушул сыяктуу материалдар узак мөөнөт бою стерилдүүлүктү сактоо үчүн эффективдүү экенин көрсөткөн. Мисалы, эриксиз беттер - бул фармацевтика жана биотехнология сыяктуу тазалык стандарттары катуу болгон иштетүү секторлорунда контаминация көрсөткүчтөрүн төмөндөтүү үчүн колдонулат.

Таза бөлме класстык стеналар менен тавандын панелдери

Таза бөлмөнүн стеналары менен тавандын панелдери кандай стандарттарга ылайык болушу керектигин билүү таза муздаткан аймакты камсыз кылуу үчүн маанилүү. Бул панелдер микробдор муздаткан ортого жол бербей тургандай, ошондой эле тазалоого болгондой кылып долбоорлонуши керек, ошондуктан аноддалган алюминий, ылайык кылынган боялар, камызылган пластмассалар сыяктуу салыштырма прочный материалдар колдонулат. Бул материалдар таза бөлмөнү модулдук түрдө куруу процессинде колдонулганда тазалыкты жана иштетүүнүн функционалдуулугун сактоого эң жакшы таасир этет. ISO жана GMP талаптарына ылайык келүү үчүн материал тандаудун маанисин документке каттоо илимий изилдөө таза бөлмөлөрдүн талаптарга ылайык келүү мүмкүнчүлүгүндө панелдери тандаардын маанилүү роль ойноорун көрсөттү. Чындыгында, туура панелдери тандаш акыркы операцияны жүргүзүү үчүн гана эмес, таза бөлмө жайлоорун иштетүү үчүн да маанилүү.

Электростатикалык разряд (ESD) эрте шешимдери

Электроникалык куралдар колдонулуучу таза бөлмөлөрдө ESD табан жабдыгын колдонуу зарыл. ESD табан жабдыгы электр статикасын жок кылат, сезгилүү бөлүктөрдү бузуп, иштетүү кемчиликтерин пайда кылат. Винил, каучук жана эпоксидди смола кармоочу модульдүү таза бөлмөлөргө ылайык келген түрдөгү ESD табан жабдыктары да бар. Тиктоолор ESD табан жабдыгын орнотуу статикалык окуялардын санын азайтып, таза бөлмөнүн иштешин камсыз кылат. Ошентип, ESD табан жабдыгын колдонуу узак мүддөттүү иштөөнү камсыз кылат жана кымбат технологиялык бөлүктөрдү коргойт.

Таза бөлмөнүн текшерилеши жана талаптарга туура келүүсү

IQ/OQ/PQ Сертификат процесстерин жүргүзүү

Орнотуу тууралуу сертификат (IQ), иштөөчү сертификат (OQ) жана өнүмдүүлүк сертификаты (PQ) сыяктуу бардык процесстер чистый бөлмөнү текшерүүнүн негизи болуп саналат. IQ бирдиктер производительдин сунуштарына ылайык орнотулгандыгын кепилдикке алат, ал эми OQ система белгиленген чектерге ылайык иштээрин расмийлештирет. PQ - бул чистый бөлмө системасы жүктөмүнүн бардыгы менен аракетсиз керектүү техникалык шарттарга ылайык иштей алаарын билдирген далил болгондуктан, эң маанилүүсү болуп саналат. Бул сертификаттар модулдук чистый бөлмө талаптарына ылайык пайдаланылып жаткан орнотууну колдоо үчүн маанилүү. Сертификатталган чистый бөлмөлөрдө текшерүүдөн өткөн бузулуштардын саны сертификатсыз бөлмөлөргө караганда көп төмөн экендигин статистикалык маалымат көрсөтүүдө. Бул сыяктуу протоколдорду киргизүү чистый бөлмөлөрдү кәсипкөй жана коопсуз деңгээлде кармоо үчүн эң маанилүү фактор экенин көрсөтөт.

Айлана-чөйрөнү көзөмөлдөө системалары

Carrier Environmental Monitoring бул таза бөлмөнүн бүтүндүгүн сактоо боюнча күзөтчү. Бул системалар тиешелүү шарттарды сактоо үчүн нарядда, аба качынтысы, температура, жылгактык жана бөлүнүү деңгээли жөнүндө маалыматты чын убакытта көзөмөлдөйт. Модульдүү таза бөлмө проектинде бул системаларды интеграциялоо чын убакытта көзөмөлдөө жана чечим кабыл алууга болгон эскертмелерди камтышы керек. Мисалы, бир нече индустриялардан алынган учурдук иликтөөлөрдө эффективдүү интеграциялоо киргизүүнүн көбөйүшүнө жеткен. БАРДАК КӨЗӨМӨЛДӨӨ КЕПИЛДИГИ Бардык өзгөрүүлөрдү эрте убакытта кабарлашы менен чабуулга каршы күрөшүп, түзөтүүгө болот – киргизүү жана сапаттын эрте эскертиши менен.

Аудитка даяр документациялык практикалар

Таза бөлме үчүн документация талаптарын аткаруу үчүн даяр документациянын мааниси чоң. Бул ыкма кагаз жана электрондук жазууларды сактоону көздөйт, анткени ал кайталанууга жана колжетимдүүлүккө мүмкүнчүлүк берет. Санариптик жазуулар заманында да кагаз жазуулар убактылуу физикалык көчүрмө катары калууда. Экинчи тараптар документациянын сапсyzдүгүнүн аягы чоң финансылык салбырларга алып келерин, стандарттарга ылайык болбогондо тергөөлөр жана иштөөнүн токтоп калышы мүмкүн экенин эскертүүдө.

Регламенттик ылайыктуулук үчүн модулдук долбоордун артыкчылыктары

Жылдам жайгаштыруу жана масштабдандыруу

Модулдуу таза бөлмө дизайнынын уламжарлык көрүнүшүнө ээ болушу, мындай күрт өсүп чыгуучу 'ӨНДҮРҮҮНҮН ЖАКШЫ ТЕХНОЛОГИЯСЫ' (GMP) талаптарын ишке ашыруу үчүн чоң көлөмдүү, чыгымдарды камсыз кылуучу курулуш проекттерин иштеп чыгууда маанилүү. Бул жерде маселенин негизги жагы - аларды көбөйтүү мүмкүнчүлүгү жана жылдам ишке киргизүү мүмкүнчүлүгү, бул жаңы регуляциялык талаптарды ишке ашырууда айрым мааниге ээ. Модулдуу таза бөлмөлөр алдын ала жасалып, уламжарлык лаборатория курулушу менен салыштырганда оңой орнотулот. Бул жол менен ынтымакташтык фармацевтика жана биотехнология секторлорундай чабук өзгөрүп турган индустриялар үчүн кошумча кыймыл алып келет, анткени жаңы регуляцияларга жана нарыктын суроолоруна кандай чабук жооп бериш өнөр жайында жарым-жартыл болушу мүмкүн. Мисалы, уламжарлык таза бөлмө курулушу бир нече ай узактыгында ишке ашырылса, модулдуу чечимдердин ишке киргизилиши эки аптанын ичинде гана ишке ашырылып, айтарлык аралык убакытты кыскартат. Бул гибкелтик институттордун таза бөлмө мейкиндигин өзгөртүүнү же өсүшүн кыска убакыт ичинде аткарып, өнөр жай талаптарынын өзгөрүшүнө ылайык келтирет.

Алдын ала долбоорлонгон ыңгайлаштыруу өзгөчөлүктөрү

Түрмөктөн түрмөккө ылайык келүүчү өнөмдүүлүк функциялары модулдук таза бөлмөлөрдө курулган. Бул функциялар фильтрация эффективдүүлүгү жана бет өңдөө контролүнө сыяктуу айрым эрежелер менен талаптарга ылайык келүү үчүн жөнгө салынган. Кийинчерээк өзгөртүүлөргө муктаж эмес. Алардын артыкчылыгы таза бөлмөнүн узак мөөнөтүндө ылайык келүүнү камсыз кылып, убакытты жана акчаны тежейт. Бүтүндөй системалар менен ылайык келүү деңгээли жогору болгонун статистикалык маалымат көрсөтүп турат. Себеби, модулдук таза бөлмөлөргө ээ компаниялар ревизиясыз же аз табылган жерлер менен жогорку деңгээлде ылайык келүүнү ишке ашырат. Бул ылайык келүүгө карата превентивдүү көз караш операциялык бүтүндүктү жана циклдык чыгымдардын тиимдүүлүгүн камсыз кылуу үчүн модулдук таза бөлмө чечимдеринин маанилүүлүгүн көрсөтөт.

Өзгөрүүгө жана стандарттарга ылайык келүүгө мүмкүнчүлүк берүүчү конфигурациялар

Модулдук таза бөлмелерде ишке көз каранды эмес иштөө жаңы эрежелер менен тез арада ылайыкташуунун бир нече ачкычтарынын бири болуп саналат. Ишканалардын талаптары өзгөрүп турган сайын ишканаларды алмаштыруу керек болбогондой чөйрөнү кайра жайгаштыруу же таза бөлмөлөрдү кеңейтүү мүмкүнчүлүгү маанилүү. Мисалы, ишке көз каранды эмес модулдук таза бөлмөлөр жабыркаган стенкалар сыяктуу факторлор менен жаңы куралдарды ишке көз каранды эмес кайра жайгаштырууну же өзгөртүүнү же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну же кайра курууну......

ЖЧК

ISO 14644 деген эмне? ISO 14644 - бул Эл аралык стандарттоо уюму тарабынан иштелип чыккан стандарттардын сериясы.

ЕС GMP 1-тиркемесинин даражалары ISO стандарттарына кандайча шайкеш келет? 1-тиркемедеги А-D класстары микробиологиялык булганууну жана аны менен байланышкан тобокелдиктерди эске алуу менен ISO 5-8 класстарына болжол менен дал келет.

Таза бөлмөлөрдө басымдын айырмасы эмне үчүн маанилүү? Басым айырмасы булгануу жолдорун көзөмөлдөө үчүн өтө маанилүү; оң басым тышкы булгануучу заттардын кирүүсүнө бөгөт коёт, ал эми терс басым потенциалдуу булгануучу заттарга ээ.

Таза бөлмөлөрдү кандай материалдар менен куруу сунушталат? Санитардык абалды камсыз кылуу жана бактериялардын жана грибоктордун өсүшүн алдын алуу үчүн дат баспаган болот, айнек жана атайын полимерлер сыяктуу поруссуз материалдар сунушталат.

Модулдуу таза бөлмөлөрдүн пайдасы кандай? Модульдүү таза бөлмөлөр өнөктүрүлгөн ыңгайлуулукту камсыз кылуу, жоболонгон ыңгайлуулук функцияларын жана өзгөрүүгө туюк конфигурацияларды тез орнотууга жана сапаттуу тармак стандарттарына ылайык келтирилген масштабтоого мүмкүнчүлүк берет.