Understanding Air Shower Fundamentals

How Air Showers Maintain Cleanroom Integrity

Air showers play a vital role in keeping cleanrooms free from dirt and particles. They work by blasting people and equipment with HEPA filtered air at high speed when they approach the entrance area. Most facilities install these units right at the doorways so anything brought in gets cleaned off before stepping into the controlled space. The location makes sense since it acts as a final checkpoint against unwanted stuff getting inside. Studies have shown these systems can cut down on microbes by almost all (around 99.9%) according to various research papers published over recent years. For pharmaceutical companies following GMP standards, this kind of performance means cleaner operations and fewer issues with product quality during manufacturing processes.

The Role of High-Velocity Airflow in Contamination Removal

Fast moving air plays a key role in getting rid of dust and dirt from people working inside cleanrooms as well as from all the equipment they use there. When air moves at high speeds, it creates turbulence that actually pushes these particles out instead of just bouncing them around, which helps keep things cleaner overall. Most cleanrooms aim for air speeds somewhere between 20 to 30 meters per second. This works hand in hand with those special HEPA filters we see everywhere, since they catch what the fast air misses. Studies looking into this have shown that keeping air moving at these speeds gives pretty good results when it comes to controlling contamination levels needed especially in places like drug manufacturing facilities where even tiny amounts of impurities can cause big problems down the line.

Differences Between Air Showers and Air Locks

Air showers and air locks play key but distinct roles within cleanroom operations. The main job of air showers is to blast away dirt and particles from workers' clothes and equipment before they step into sensitive areas. Think of them as those high velocity blasts we see in pharmaceutical labs or semiconductor factories. Air locks work differently though. They create barriers between the clean space inside and whatever's outside, keeping unwanted stuff from sneaking in through doorways. Most air lock systems have automatic doors that only open one at a time, preventing cross contamination. When choosing between these options, facility managers need to consider their particular requirements. Some industries need multiple layers of protection while others might get by with just one solution. Getting this right matters a lot because improper setup can lead to costly product recalls or regulatory issues down the road.

Key Components of Air Shower Standards

HEPA/ULPA Filtration Requirements

HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filters play a key role in making sure air showers actually deliver clean air without contaminants. The specs for these filters are pretty strict too. HEPA needs to filter out at least 99.97% of particles while ULPA goes even further at around 99.999%. Pharmaceutical companies following GMP guidelines for their cleanrooms have to replace and test these filters regularly according to schedule. Otherwise, the whole point of having cleanrooms gets compromised when outside dirt finds its way in through old or damaged filters. Regular maintenance isn't just good practice it's basically essential for keeping sensitive manufacturing processes free from contamination risks.

Nozzle Configuration and Airflow Velocity Guidelines

How nozzles are set up in air showers really matters when it comes to controlling where the air goes and how fast it moves, since both factors determine if the decontamination works properly. Most industry guidelines give specific measurements for nozzle angles and sizes that help spread out the air better, making sure particles get knocked loose from surfaces. For best results, most experts recommend keeping the air speed somewhere around 20 to 30 feet per second. When companies need to meet cleanroom requirements, they usually check their nozzle setups to see if everything supports good contamination control practices. This helps ensure the whole system actually does what it's supposed to do for cleaning purposes.

Cycle Time and Dwell Time Specifications

The cycle time and dwell time matter a lot when it comes to air showers, affecting how well and how fast people can get through into cleanrooms. Cycle time basically means how long an entire air shower lasts from beginning to end, which determines just how quickly staff members can move into their work areas. Dwell time is different though it's about how long someone stays under those powerful air jets that blow away dirt and particles before entering sensitive spaces. Most cleanroom guidelines suggest somewhere between 15 and 30 seconds for dwell time depending on what kind of cleanroom standards they need to meet. Looking at these numbers regularly and making adjustments where needed helps boost overall performance while keeping unwanted stuff out of controlled environments.

GMP and ISO Compliance in Air Shower Design

Meeting Pharmaceutical Cleanroom Requirements

When designing air showers for pharmaceutical cleanrooms, they really need to follow those strict GMP guidelines if we want them to work properly. Meeting these standards means going through all sorts of validation checks that look at both how well the air showers themselves perform and whether the whole cleanroom environment stays intact. Sticking to GMP isn't just good practice either it actually makes a big difference in cutting down on contamination problems and keeping products safe for patients. Most manufacturers know this from experience after dealing with costly recalls caused by poor compliance. Regular checkups and site visits become part of daily operations to stay within all the health and safety rules set for drug manufacturing plants. Industry reports keep coming out showing that companies which stick closely to GMP standards tend to see fewer contamination issues over time, which obviously leads to better quality drugs reaching consumers.

ISO Class Alignment for Controlled Environments

The ISO classification system plays a key role when it comes to figuring out what counts as acceptable particle levels and overall air cleanliness, which directly influences how we design and build air showers. When air shower systems follow these ISO guidelines, they create environments that stay consistently clean whether for manufacturing products or conducting scientific research. Take ISO Class 5 for instance, where the limit stands at 3,520 particles per cubic meter. Meeting this standard demands proper functioning of air showers throughout their operation cycle. Beyond just being another technical spec sheet item, sticking to these ISO requirements matters quite a bit during regulatory inspections too. Failure to comply could lead to serious consequences down the road including potential issues with product liability claims later on.

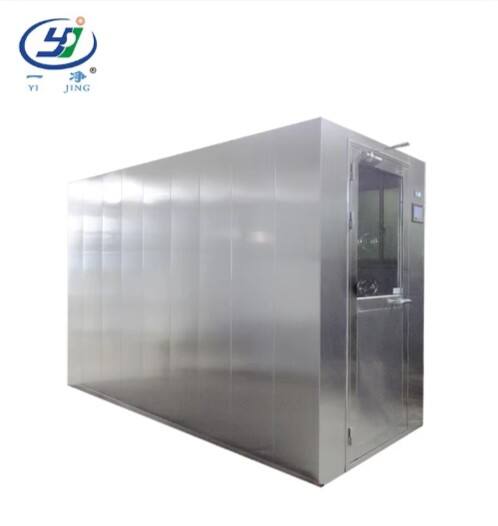

Material Selection for Chemical Resistance

Building air showers from materials that can handle chemical exposure matters a lot, especially inside pharmaceutical cleanrooms where all sorts of solvents and harsh chemicals hang around. Stainless steel remains popular because it holds up well against repeated cleaning cycles, while certain polymer options have become go-to choices for their resistance to wear and tear over time. Industry regulations actually specify which materials must be used in these spaces to keep workers safe and equipment functioning properly despite constant contact with corrosive agents. What gets chosen for construction affects how long the system lasts and how much money goes toward upkeep down the road. For anyone involved in designing or building these critical facilities, picking the right materials isn't just about meeting specs it's about balancing long term performance with budget realities.

Optimizing Air Shower Performance

Protocols for Effective Personnel Rotation

Strict personnel rotation rules really matter when it comes to keeping contamination at bay in cleanrooms. When facilities organize how staff members come in and go out systematically, they cut down on cross contamination between workers who handle sensitive materials. Most companies find that regular training sessions help everyone remember proper procedures, especially around using those air showers correctly before entering restricted areas. Some folks just forget or get lazy over time, so constant reminders work best. Industry regulations typically suggest different rotation schedules depending on what kind of risks exist in particular cleanrooms. For instance, semiconductor manufacturing spaces usually need stricter rotations than pharmaceutical labs because of the nature of their products. These guidelines aren't set in stone though many manufacturers adjust them based on their own experiences with contamination issues.

Psychological Impact on Contamination Awareness

The way people think and feel actually makes a big difference when it comes to following contamination control rules inside cleanrooms. When companies run training sessions that really drive home why air showers matter so much for keeping things clean, workers tend to follow protocols more consistently. Studies from various facilities show that when staff understand exactly how contaminants can ruin products or compromise experiments, they start being more careful about their routines. We've seen this happen time and again where teams develop a real sense of responsibility for maintaining those high standards. Cleaner environments result not just from better equipment but also from employees who genuinely care about what happens in their workspace day after day.

Energy Efficiency and Maintenance Cost Reduction

When air showers run at their best, companies often see real money saved on operating costs, especially when it comes to how much power they consume. Maintenance isn't just about fixing things when they break down either. Regular checkups keep those airflow rates working properly and make sure filters aren't getting clogged up, both of which affect how much electricity gets used day after day. Many businesses find that switching to newer, more energy conscious models pays off over time while helping them stay within green regulations. Some studies point to around 15% or more in potential savings from proper energy assessments, which makes sense why so many facility managers are focusing harder on making these cleaning stations work smarter rather than just harder.

Air Shower Maintenance and Validation Protocols

Filter Replacement Schedules per Industry Standards

Getting those filter replacement schedules right makes all the difference when it comes to keeping air showers working properly in cleanrooms. Most industry guidelines point towards checking filters roughly every six months to a year depending on how heavily they're used day to day. Sticking with this routine matters a lot because skipping replacements means poorer air quality and bigger chances of contamination creeping in, especially where things need to stay super sterile like in pharma labs. Keeping records of when filters get swapped out isn't just paperwork either it helps meet regulations and creates a paper trail that auditors will want to see. When companies actually follow through on these maintenance plans, they protect both their operations and the delicate products being manufactured inside those cleanrooms from getting compromised by dirt or microbes.

Particle Count Testing for Performance Verification

Particle count testing needs to happen regularly to check whether air showers stay within their particulate matter limits. During normal operations, technicians collect air samples right from inside the air shower itself to see how well the filters are actually working. When test results come back, they get compared to those standard thresholds we all know about. If numbers go above what's allowed, then something needs fixing pretty quick. This kind of testing isn't just about ticking boxes for regulations either. It really does make a difference in day-to-day safety across most facilities. Proper functioning air showers mean fewer contamination issues down the line, which keeps everything running smoothly according to both clean room standards and those important GMP requirements manufacturers have to follow.

Documentation Requirements for Regulatory Audits

Cleanrooms need thorough documentation if they want to pass regulatory audits. Most auditors will want to see records showing when equipment was maintained, filters changed, and how many particles were counted during tests. A good documentation system makes audits go smoother and helps keep everyone accountable for following procedures properly. These records aren't just paper work though they actually help spot problems early on. For instance, if there's a sudden spike in particle counts, the documentation shows exactly when it happened and what might have caused it. Facilities that stick to proper documentation standards maintain compliance and build confidence among clients who care about contamination controls. After all, nobody wants to deal with recalls or production delays because someone forgot to log something important.

FAQ

What is the main function of an air shower in a cleanroom?

Air showers are designed to remove contaminants from personnel and materials before entering a cleanroom, ensuring the environment remains free from particulate contamination.

How often should HEPA/ULPA filters be replaced in air showers?

HEPA/ULPA filters should typically be inspected every six to twelve months, and replaced as needed, to maintain optimal air shower performance.

What is the recommended airflow velocity for air showers?

The recommended airflow velocity for effective contamination control in air showers is between 20-30 meters per second.

How do air showers differ from air locks in cleanrooms?

Air showers remove contaminants from personnel and materials entering cleanrooms, while air locks regulate pressure differentials between the cleanroom and external environments.

Why is documentation important in air shower operations?

Documentation is crucial for meeting regulatory audit requirements, enabling continuous improvement and ensuring accountability in contamination control measures.