The Critical Importance of Clean Room Environments in Semiconductor Manufacturing

Particle Control at Sub-Micron Levels

Controlling those tiny sub-micron particles remains one of the biggest headaches in semiconductor manufacturing, directly affecting how many chips actually work and their overall performance. The truth is, these components are so sensitive that just one speck of dust at microscopic level can ruin entire batches worth millions for manufacturers. That's why modern cleanrooms need to get down to contamination levels way under 0.1 microns to keep product quality intact. Most facilities invest heavily in high-end air filtration setups like HEPA and ULPA filters. But maintaining this kind of ultra-clean environment isn't easy either, requiring constant monitoring and maintenance to prevent even the smallest contaminant from causing major problems during production runs.

Research across manufacturing sectors shows just how big of a problem particle contamination really is. Take sub-micron particles for instance they cause all sorts of defects that end up costing companies serious money. Some reports talk about individual incidents running into the millions when things go wrong because of these tiny contaminants. Semiconductor manufacturers know this better than anyone else. Their cleanrooms need to be spotless, almost like operating rooms in hospitals. Maintaining such strict standards isn't easy though. Every day brings new challenges in keeping those pesky particles out of sensitive equipment where even the smallest speck can ruin entire batches worth thousands.

ISO Classifications and Semiconductor Yield Rates

The ISO standards, particularly ISO 14644, play a big role in determining how many good chips come out of semiconductor manufacturing. Basically, these standards sort cleanrooms into different categories based on how many particles float around in each cubic meter of air. The classes range from super clean Class 1 all the way up to Class 100 which still has some dust but not too much. Different parts of chip making need different levels of cleanliness. Take photolithography for example most of the time this happens in those ultra clean Class 1 rooms where even the tiniest speck could ruin everything. Keeping things this clean helps manufacturers get better results and avoid wasting materials on defective products.

Following strict standards really matters when it comes to boosting both production speed and the quality of products made. Take companies such as Intel or TSMC for example they've put in place pretty tough ISO requirements across their operations. These rules help keep contaminants at bay while making sure everything runs smoother on the factory floor. Looking at actual results from these big players shows something interesting yields go up noticeably and chips come out better overall. That's why most serious manufacturers stick so closely to those cleanroom protocols during production runs, even though it takes extra effort and resources to maintain them properly.

Economic Impacts of Contamination Breaches

When contamination happens in semiconductor fabrication plants, it can wreck havoc on businesses financially. These problems usually mean extra work getting products right again, lost time during production runs, and sometimes even losing ground against competitors in the market. According to various industry sources, fixing these messes typically costs companies several million dollars each time they occur, which really eats away at profits. Looking further ahead, there are bigger issues than just money at stake. Companies dealing with repeated contamination problems tend to struggle with their reputation over time, and customers start looking elsewhere for reliable suppliers as trust erodes gradually.

In industries where precision matters most, reputation and reliability simply cannot be ignored. When talking about semiconductors, even the smallest contamination issues can ruin everything for businesses, which explains why so many clients start looking elsewhere when problems arise. Keeping things clean isn't just about following rules anymore it's become absolutely essential for staying in business. Semiconductor manufacturers know this all too well these days. Cleanrooms need strict protocols, equipment must be maintained properly, and every step of production requires careful attention. Companies that fail to maintain these standards risk losing customers fast in what's already a highly competitive market.

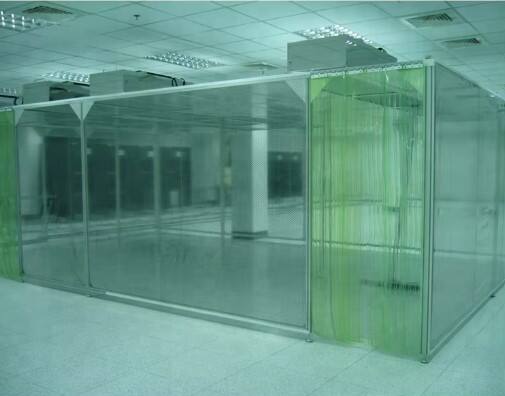

Benefits of Modular Clean Rooms for Semiconductor Facilities

Scalability for Evolving Fabrication Processes

The semiconductor manufacturing world changes fast, and modular clean rooms are becoming essential because they can grow and change as needed. When new tech nodes come along and factories need to tweak their processes, these modular setups let companies expand or modify spaces without shutting everything down for weeks. Take a look at what happened at TSMC last year when they had to update their cleanrooms for 3nm chips. They were able to add new modules during regular maintenance periods instead of doing a complete overhaul. Semiconductor plants across Asia have shared stories about how switching to modular designs saved them time and money while still meeting strict contamination standards. The bottom line is that flexible cleanroom solutions help manufacturers stay competitive in this constantly shifting market landscape.

Cost-Effective Reconfiguration Capabilities

Modular clean rooms offer real money savings benefits, especially when manufacturers need to change around their factory floor setups for different product runs. Traditional cleanroom installations typically come with steep price tags for building and running them, but modular versions cut down on those costs dramatically. Companies across various industries have reported spending less upfront and saving even more over time with these adaptable spaces. For instance, pharmaceutical firms often find themselves needing to switch between drug formulations, and modular systems let them do this without breaking the bank. The money saved isn't just nice to have it directly affects profitability since businesses can redirect funds toward other critical areas while still keeping production flexible enough to meet changing demands in the market.

Rapid Deployment in Existing Facilities

Modular designs really speed things up when it comes to getting semiconductor facilities running, letting them go live faster with far less disruption to surrounding areas. When working inside already built structures, these modular clean rooms can be put together in a fraction of the time needed for traditional building approaches. Take TSMC for instance they slashed their setup period by half when switching to modular components, which kept their production lines from sitting idle during construction. The fact that manufacturers can just bolt on new sections or replace old ones means their factories stay productive throughout expansions or upgrades. This flexibility makes all the difference in an industry where every day lost counts against profit margins and market position.

Design Innovations in Modular Clean Room Technology

Advanced Air Handling Units for Precision Control

Air handling units today are really important for keeping air quality at the right levels inside those super clean rooms where even tiny particles can cause problems. The modern versions come packed with all sorts of cool tech stuff like filters that catch almost everything and controls that let engineers tweak airflow down to the last detail. We've seen some pretty neat improvements lately too - better HEPA filters that trap more contaminants, plus computerized systems that constantly monitor conditions and adjust automatically. When it comes to semiconductor manufacturing facilities specifically, these upgrades make all the difference because their cleanrooms need to be spotless for making those microscopic chips. Without this kind of advanced equipment, manufacturers just wouldn't be able to meet the incredibly tight specifications demanded by today's high-tech production requirements.

Mobile Clean Room Solutions for Flexible Operations

The flexibility of mobile clean rooms makes them ideal for all sorts of production requirements since they can adjust pretty well to different manufacturing workflows. For R&D departments especially, these portable units are a game changer when it comes to product development cycles. Researchers can test prototypes multiple times over without dealing with the limitations of fixed infrastructure. The market has seen growing interest in mobile clean room technology because companies need solutions that can go up fast and change configuration whenever necessary. Manufacturers dealing with fluctuating order volumes find these systems particularly useful. They simply roll out the clean room setup wherever needed and modify it according to current project specifications, which explains why so many forward thinking businesses now consider mobile options essential for staying competitive in today's dynamic manufacturing landscape.

ESD-Compliant Materials for Static-Sensitive Environments

ESD compliant materials are absolutely essential in cleanrooms where they protect those delicate semiconductor chips from damaging static electricity. Most facilities implement several basic strategies these days ground flooring systems, work tables that dissipate static charges, and special clothing made from conductive fabrics. These approaches have pretty much become standard practice across the industry because they actually work at preventing ESD problems. When companies properly manage static control, they see fewer product failures during manufacturing processes, which means better yields overall. Industry reports consistently show that implementing proper ESD controls cuts down on component failures by significant margins. For anyone running a cleanroom that handles semiconductors, incorporating these materials isn't just recommended it's practically non-negotiable if they want to maintain quality standards and avoid costly production setbacks.

Integration with Semiconductor Manufacturing Processes

Photolithography-Compatible Environmental Controls

Photolithography remains a key process in semiconductor manufacturing where environmental conditions matter a lot. Cleanrooms must maintain tight control over temperature and humidity because even small fluctuations can mess up the whole production run. When talking about actual numbers, keeping humidity around 40 to 50 percent helps prevent problems when applying photoresist materials, which leads to cleaner circuit patterns and reduces those frustrating defects we all want to avoid. Temperature management is equally important since silicon wafers expand and contract with heat changes, potentially causing alignment issues during processing. Most manufacturers specify exact ranges based on their equipment specs, so following these guidelines closely makes a real difference in day-to-day operations. The result? Better yields, fewer rejected batches, and ultimately happier customers who get reliable chips for their devices.

Raised Floor Systems for Utility Distribution

In semiconductor manufacturing plants, raised floor systems bring real benefits when it comes to managing utilities and controlling airflow throughout the facility. The way these floors work allows air to move efficiently through the space, which helps keep everything clean and maintains stable environmental conditions that are so important for chip fabrication. Another big plus is how much easier it becomes to reach wiring and plumbing without causing disruptions or messing up the ultra-clean environment needed for producing semiconductors. And contrary to what some might think, this kind of accessibility doesn't actually introduce contamination risks since modern sealed flooring acts as a barrier against dust and other particles getting into sensitive work areas. Facilities that have gone with raised floor installations typically see better performance metrics across the board. Maintenance teams spend less time troubleshooting infrastructure issues, while production lines can run at higher capacities because technicians aren't constantly battling inaccessible components buried beneath traditional flooring.

Night Mode HVAC for Energy Efficiency

The night mode feature in HVAC systems represents a clever approach to cutting down on energy usage in semiconductor manufacturing facilities when they're not actively running operations. When factories switch to this mode after hours, they tweak their temperature controls and adjust how air moves through the building, which cuts back on power needs quite a bit while still keeping those expensive machines safe from damage. Many chip makers across Asia and North America have already rolled out night mode systems with pretty good results. According to recent reports from industry experts, these nighttime adjustments typically save around 15% on overall energy bills, which adds up to real money saved over time and helps cut carbon emissions too. The bottom line is simple enough: most plants find that they can keep everything running smoothly through the night without wasting electricity, something that makes sense both financially and environmentally speaking.

Case Studies: Modular Success in Semiconductor Production

Arizona Facility: Dual-Purpose R&D/Manufacturing Design

The Arizona plant stands out as one of those rare cases where they actually pulled off a modular cleanroom setup that works for both research and manufacturing at the same time. What makes this design so good is how it lets them switch back and forth between developing new products and cranking out finished goods without tearing everything apart each time. The real benefit? They've seen their production numbers jump quite a bit since implementing this system last year. Looking at the numbers after rollout shows around 30% increase in monthly output compared to before. This matches up nicely with what management was hoping to achieve when they first started talking about making operations more flexible and getting better results from their space.

High-Volume Fab Conversion Using Prefabricated Modules

One major semiconductor fabrication plant made great strides by adopting modular prefabrication techniques to boost its production capabilities. When they started integrating these prefabricated components into their workflow, they managed to switch quickly from low to high volume manufacturing. The whole transition wasn't exactly smooth sailing though. Management spent months mapping out every step, making sure there would be no gaps when bringing in these new modules while keeping existing operations running. Looking at what happened after the switch, the results speak for themselves. Output jumped significantly, and day-to-day operations became much more efficient. This real-world example shows just how effective modular approaches can be when companies need to scale up production rapidly without breaking the bank or causing major disruptions.

Mobile Clean Rooms for Equipment Prototyping

The advent of mobile clean rooms has changed how we approach equipment prototyping, mainly because they offer flexibility and can be adapted right where needed. These portable units let engineers work on prototypes at different sites, which makes handling special requirements much easier for every individual project. Real world applications show just how effective these mobile setups can be, with some companies reporting cuts in development time and better overall results from their projects. What makes them so valuable is the fact that they create a controlled space no matter where they're deployed, allowing teams to move quickly through the prototyping phase while still maintaining high standards for both quality and hygiene.

Future-Proofing Semiconductor Clean Rooms

Smart Monitoring Systems for Real-Time Validation

Smart monitoring systems are now playing a major role in validating conditions inside semiconductor clean rooms in real time. These tech solutions offer continuous surveillance along with immediate data updates so environmental factors stay within required ranges something absolutely necessary for those super sensitive manufacturing operations. With recent advances in automation, such systems help keep things aligned with the strict cleanliness standards set by the industry while cutting down on mistakes made by people. Major players in the field including Intel and Samsung have already adopted these real time monitoring approaches to fine tune their clean room setups. Take a look at what happens when companies get access to live data they can spot issues before they become problems, schedule maintenance work ahead of time instead of reacting to breakdowns, and generally run smoother operations with fewer interruptions. This translates into better productivity numbers and higher quality products coming off the line.

Adaptive Filtration for Next-Gen Node Manufacturing

The rise of adaptive filtration tech has made a big difference in semiconductor node manufacturing lately. These filtration systems can adjust on the fly to different environmental factors which means better particle control overall. Tests and field data indicate these systems grab those really tiny contaminants that slip through traditional filters, keeping production lines clean. Take TSMC for instance their factories saw significant drops in submicron particles after implementing this technology, which translated into better performing chips across the board. Cleaner air means fewer defects and higher output numbers, so manufacturers are scaling up these filtration solutions as they push forward with next generation node production requirements.

Sustainable Materials in Modular Construction

Clean rooms in the semiconductor sector are slowly making the switch to greener building materials as companies try to balance their environmental impact without compromising on cleanliness standards. We're seeing things like recycled aluminum frames and those special low-VOC paints getting used more frequently in new constructions. These changes help manufacturers meet various green certifications they need for operations these days. The push comes from both regulatory pressures worldwide and genuine efforts by firms to cut down emissions. Looking at recent numbers, there's been about a 15% rise each year in projects using these eco options. What started as niche experimentation is now becoming something of an industry norm when it comes to constructing facilities that handle sensitive semiconductor manufacturing processes.

FAQ

What is the importance of particle control in semiconductor manufacturing?

Particle control is crucial because even a single microscopic particle can lead to defects in semiconductors, influencing yield rates and device performance. Cleanrooms are designed to minimize contamination, ensuring product integrity.

How do ISO classifications impact semiconductor yield rates?

ISO classifications, such as ISO 14644, categorize cleanrooms by particle density, affecting production rates. Adhering to these standards helps optimize manufacturing processes, thus improving yield rates and product quality.

Why are modular clean rooms beneficial for semiconductor facilities?

Modular clean rooms offer scalability, cost-effectiveness, and rapid deployment, enabling semiconductor facilities to evolve with technological advancements without substantial disruptions.

Table of Contents

- The Critical Importance of Clean Room Environments in Semiconductor Manufacturing

- Benefits of Modular Clean Rooms for Semiconductor Facilities

- Design Innovations in Modular Clean Room Technology

- Integration with Semiconductor Manufacturing Processes

- Case Studies: Modular Success in Semiconductor Production

- Future-Proofing Semiconductor Clean Rooms

- FAQ