How to Choose the Right Clean Panel Material for Wall Systems

Clean panel materials have become essential in modern construction, used in environments where hygiene, durability, and easy maintenance are critical. From hospitals and laboratories to commercial kitchens and cleanrooms, clean panels create wall systems that resist stains, repel moisture, and stand up to frequent cleaning. Choosing the right clean panel material ensures your wall system meets the specific needs of the space, whether it’s preventing bacterial growth in a healthcare setting or withstanding harsh chemicals in an industrial facility. This guide explains how to select the best clean panel material for wall systems, covering key factors, material types, and practical considerations.

What Are Clean Panel Materials for Wall Systems?

Clean panel materials are specialized cladding products designed for wall systems in environments requiring high levels of cleanliness and durability. Unlike traditional wall materials (such as paint or drywall), clean panels are engineered to have smooth, non-porous surfaces that resist dirt, moisture, and bacteria. They are easy to clean with harsh disinfectants or detergents, making them ideal for spaces where hygiene is a priority.

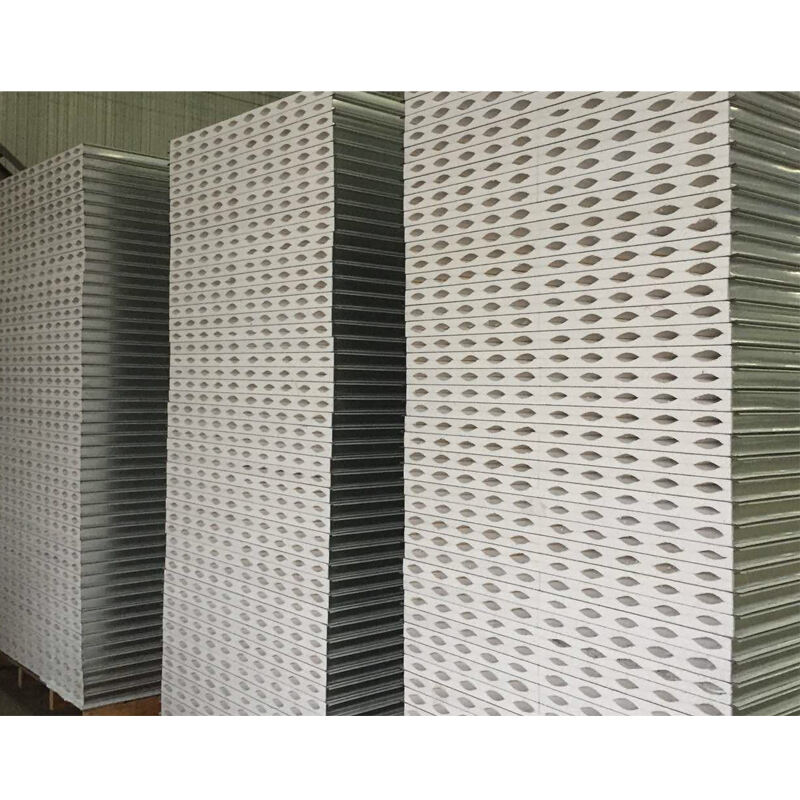

Clean panels for wall systems are typically made from synthetic or metal materials, often with a core (like foam or plywood) sandwiched between protective outer layers. They come in various forms, including sheets, tiles, or panels that interlock for seamless installation, reducing gaps where dirt or bacteria could hide. The right clean panel material depends on the space’s unique demands, such as exposure to moisture, chemicals, or heavy use.

Key Factors to Consider When Choosing Clean Panel Materials

1. Application and Environment

The first step in choosing a clean panel material is to assess the environment where the wall system will be installed. Different spaces have distinct needs that influence material selection:

- Healthcare Settings (Hospitals, Clinics): Require clean panels that resist bacteria growth and can withstand frequent disinfection with strong chemicals (like bleach). Antimicrobial properties and non-porous surfaces are critical here.

- Food Service (Commercial Kitchens, Cafeterias): Need clean panels that resist heat, grease, and moisture. They must handle daily cleaning with hot water and food-safe detergents without warping or staining.

- Laboratories and Cleanrooms: Demand clean panels that resist chemical spills (acids, solvents) and maintain airtight seals to prevent contamination. Low particle emission is also important.

- Industrial Facilities: Require durable clean panels that withstand impacts, abrasion, and exposure to oils or coolants. Fire resistance may also be a priority.

- Residential or Office Spaces: Focus on clean panels that balance aesthetics with easy maintenance, such as resistance to stains or moisture in bathrooms or laundry rooms.

Example: A hospital operating room needs a clean panel material with antimicrobial additives to reduce infection risks, while a commercial kitchen wall system requires heat-resistant panels that repel grease.

2. Material Properties

Clean panel materials vary in their physical and chemical properties, which directly affect performance. Key properties to evaluate include:

- Hygiene: Look for non-porous surfaces that prevent bacteria, mold, or mildew from thriving. Some clean panels include antimicrobial coatings (like silver ions) that actively kill microbes.

- Durability: Assess resistance to impacts, scratches, and wear. In high-traffic areas (like hospital corridors), a scratch-resistant clean panel will maintain its appearance longer.

- Moisture Resistance: Critical for humid environments (bathrooms, kitchens, labs). Water-resistant clean panels prevent warping, swelling, or rot, which can compromise the wall system.

- Chemical Resistance: Important for spaces using harsh cleaners or chemicals. Clean panels should resist staining, discoloration, or degradation when exposed to disinfectants, acids, or solvents.

- Fire Resistance: Required in many commercial and industrial settings. Check for fire ratings (e.g., ASTM E84) to ensure the clean panel material meets local safety codes.

- Ease of Cleaning: Smooth, non-textured surfaces are easier to wipe down. Avoid clean panels with seams or grooves that trap dirt—seamless designs reduce cleaning time and improve hygiene.

3. Installation and Maintenance

The practicality of installing and maintaining the clean panel material is another key consideration:

- Installation Complexity: Some clean panels require professional installation with specialized tools, while others are designed for easy DIY mounting. Interlocking or adhesive-backed clean panels can speed up installation and reduce labor costs.

- Seam Handling: Gaps between panels can harbor dirt, so choose clean panels with tight-sealing systems (like tongue-and-groove edges) or options for seamless installation.

- Maintenance Needs: Consider how often the wall system will need cleaning and whether the material requires special care. For example, some metal clean panels may need polishing to maintain shine, while PVC panels can be cleaned with simple soap and water.

- Repairability: Can damaged panels be easily replaced? In high-use areas, a clean panel material that allows for individual panel replacement (instead of redoing the entire wall) saves time and money.

4. Aesthetics and Design

While functionality is priority, clean panel materials should also fit the space’s design needs:

- Color and Finish: Clean panels come in a range of colors and finishes (matte, glossy, textured). In healthcare settings, light colors can create a bright, sterile look, while commercial kitchens may opt for dark colors to hide grease stains.

- Customization: Some manufacturers offer custom sizes, colors, or prints for clean panels, allowing them to match branding or design themes.

- Light Reflection: Glossy finishes can reflect light, making spaces feel brighter, but may show fingerprints more easily. Matte finishes are better for hiding smudges in high-touch areas.

5. Cost and Longevity

Evaluate both upfront and long-term costs:

- Initial Cost: Clean panel materials vary in price. For example, stainless steel panels are more expensive upfront than PVC, but may last longer.

- Lifespan: A durable clean panel material with a 15–20 year lifespan may be more cost-effective than a cheaper option that needs replacement every 5 years.

- Maintenance Costs: Consider ongoing expenses, such as special cleaners or professional maintenance. Low-maintenance materials (like FRP) can reduce long-term costs.

Common Clean Panel Materials for Wall Systems

1. Stainless Steel

Stainless steel is a popular clean panel material for high-hygiene environments. It is non-porous, resistant to bacteria, and withstands frequent cleaning with harsh chemicals.

- Pros: Exceptionally durable, fire-resistant, and compatible with food-safe and medical-grade disinfectants. It has a sleek, modern appearance and is 100% recyclable.

- Cons: Higher upfront cost than other materials. Can dent if hit with heavy objects and may show fingerprints or scratches.

- Best For: Hospitals, operating rooms, commercial kitchens, and laboratories where hygiene and chemical resistance are critical.

2. PVC (Polyvinyl Chloride)

PVC clean panels are affordable, lightweight, and easy to install, making them a common choice for commercial and residential settings.

- Pros: Water-resistant, low-cost, and available in a wide range of colors and finishes. They resist mold, mildew, and most household chemicals, and are easy to clean with soap and water.

- Cons: Less heat-resistant than metal panels (may warp at high temperatures). Not as durable as stainless steel—prone to scratching or denting under heavy use.

- Best For: Bathrooms, laundry rooms, fast-food kitchens, and low-traffic commercial spaces where cost and moisture resistance are priorities.

3. FRP (Fiberglass-Reinforced Plastic)

FRP clean panels consist of a plastic resin reinforced with fiberglass, creating a strong, flexible material.

- Pros: Highly durable, impact-resistant, and moisture-proof. FRP panels are resistant to chemicals and easy to install with adhesive. They are more affordable than stainless steel but more durable than PVC.

- Cons: Not as heat-resistant as metal. May fade in direct sunlight over time. Seams require careful sealing to prevent moisture intrusion.

- Best For: Industrial kitchens, laboratories, schools, and high-moisture areas like locker rooms or pool facilities.

4. Acrylic

Acrylic clean panels offer a glossy, glass-like finish with good hygiene properties. They are made from a type of plastic known for clarity and durability.

- Pros: Non-porous, scratch-resistant, and easy to clean. Acrylic panels resist stains and most household chemicals, and their glossy finish reflects light, brightening spaces.

- Cons: More expensive than PVC but cheaper than stainless steel. Can crack under heavy impact and may yellow over time with exposure to UV light.

- Best For: Dental clinics, retail spaces, and residential bathrooms where aesthetics and moderate durability are important.

5. Aluminum Composite Panels

Aluminum composite panels (ACPs) consist of two thin aluminum sheets bonded to a core (often plastic or mineral-filled). They combine the durability of metal with lightweight properties.

- Pros: Strong, weather-resistant, and fire-retardant (with mineral cores). They have a smooth finish that resists moisture and are available in various colors.

- Cons: Higher cost than PVC or FRP. The core material may be vulnerable to damage from harsh chemicals. Requires professional installation to ensure proper sealing.

- Best For: Exterior wall systems, cleanrooms, and industrial facilities where strength and weather resistance are needed.

6. Solid Surface Panels

Solid surface panels (made from materials like Corian) are non-porous, seamless, and customizable, offering both hygiene and design flexibility.

- Pros: Seamless installation (no gaps for dirt), stain-resistant, and repairable—scratches or dents can be sanded out. They are compatible with food-safe cleaners.

- Cons: Expensive upfront. Less heat-resistant than metal (may scorch if exposed to open flames). Not as impact-resistant as FRP or stainless steel.

- Best For: High-end commercial kitchens, luxury bathrooms, and healthcare facilities where aesthetics and seamless hygiene are priorities.

Real-World Examples of Clean Panel Material Selection

Hospital Operating Room

A hospital chooses stainless steel clean panels for its operating rooms. The material’s non-porous surface resists bacterial growth, and it withstands daily cleaning with strong disinfectants. Its durability ensures the wall system remains intact despite heavy equipment movement and frequent use.

Commercial Bakery

A bakery uses FRP clean panels for its kitchen walls. The panels resist moisture from steam and daily cleaning, while their impact resistance stands up to carts and equipment bumps. FRP’s affordability fits the bakery’s budget, and its easy maintenance reduces downtime.

Laboratory

A chemical lab installs aluminum composite clean panels with a mineral core. The panels resist spills from acids and solvents, while their fire-retardant properties meet safety codes. The seamless design prevents chemical residues from hiding in gaps, maintaining a contamination-free environment.

Residential Bathroom

A homeowner selects PVC clean panels for their bathroom renovation. The panels are water-resistant, easy to install, and come in a marble finish that matches the bathroom’s design. They resist mold and are affordable, making them ideal for a high-moisture residential space.

FAQ

What is the most hygienic clean panel material?

Stainless steel is the most hygienic option due to its non-porous surface and resistance to bacteria growth. It is compatible with medical-grade disinfectants, making it ideal for hospitals and labs.

Which clean panel material is best for high-moisture areas?

FRP and PVC are excellent for high-moisture areas like bathrooms or kitchens. Both are water-resistant, preventing warping or mold growth even with daily exposure to water.

How long do clean panel wall systems typically last?

Lifespan depends on the material: PVC panels last 5–10 years; FRP and acrylic last 10–15 years; stainless steel and aluminum composite panels can last 20+ years with proper maintenance.

Can clean panels be painted or customized?

Some materials can be customized: PVC and FRP panels come in pre-colored options, while solid surface panels can be cut to size or shaped for unique designs. Stainless steel and aluminum panels are harder to paint but available in custom finishes.

Are clean panel materials eco-friendly?

Stainless steel and aluminum are highly recyclable, making them eco-friendly choices. PVC and FRP are less recyclable but have low maintenance needs, reducing long-term environmental impact. Look for panels made from recycled materials or low-VOC (volatile organic compound) formulations for greener options.