What Are Clean Panels and Where Are They Used in Clean Rooms?

Clean rooms are controlled environments designed to minimize contamination from particles, microbes, and other pollutants, critical for industries like pharmaceuticals, electronics, and healthcare. To maintain these strict cleanliness standards, every component of a clean room—including its walls, ceilings, and floors—must meet specialized requirements. Clean panels are a key building block in this context, providing durable, easy-to-maintain surfaces that support the integrity of clean room environments. This guide explains what clean panels are, their key features, and where they are used in clean rooms across various industries.

What Are Clean Panels?

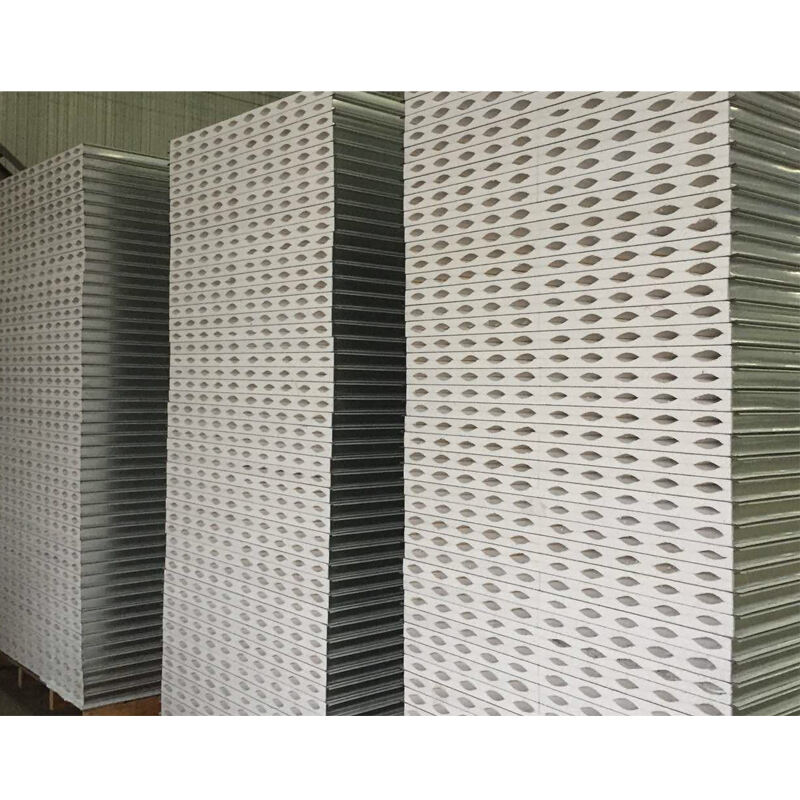

Clean panels are specialized building materials engineered for use in environments where cleanliness, low particle emission, and durability are essential. Unlike traditional construction materials such as drywall or painted concrete, clean panels are designed to minimize gaps, pores, and irregular surfaces that can trap particles or harbor microbes.

Most clean panels consist of a core material (often made of foam, plywood, or mineral fiber) sandwiched between two protective outer layers. These outer layers are typically made from materials like stainless steel, aluminum, PVC, or fiberglass-reinforced plastic (FRP), chosen for their smooth, non-porous properties. The panels are manufactured to tight tolerances, ensuring they fit together seamlessly with minimal gaps, reducing the risk of particle accumulation.

Key characteristics of clean panels include:

- Non-porous surfaces: Prevent particles, liquids, or microbes from penetrating the material.

- Low particle shedding: Do not release fibers, dust, or debris that could contaminate the clean room.

- Chemical resistance: Withstand frequent cleaning and disinfection using harsh agents like bleach or alcohol.

- Durability: Resist impacts, scratches, and wear from equipment, tools, or foot traffic.

- Airtightness: When installed with proper seals, they prevent air leakage between clean room zones.

Key Features of Clean Panels for Clean Rooms

Clean panels are specifically optimized to meet the unique demands of clean room environments. Their design focuses on four critical features:

1. Contamination Control

The primary role of clean panels in clean rooms is to reduce contamination risks. Their non-porous surfaces leave no space for particles, bacteria, or mold to hide, making them easy to clean thoroughly. Unlike porous materials (such as painted wood), which can absorb spills or harbor microbes, clean panels create a barrier that repels liquids and prevents microbial growth. This is especially important in sterile environments like pharmaceutical clean rooms, where even a single microbe could compromise product quality.

Many clean panels also undergo specialized treatments to further reduce contamination. For example, some stainless steel clean panels are polished to a high sheen, minimizing surface irregularities that could trap particles. Others may include antimicrobial coatings (infused with silver ions, for instance) that actively inhibit bacterial growth between cleanings.

2. Easy Cleaning and Maintenance

Clean rooms require frequent and rigorous cleaning to maintain their classification (e.g., ISO 5 or ISO 8, which define allowable particle counts). Clean panels are designed to simplify this process. Their smooth, flat surfaces can be quickly wiped down with disinfectants, and their seamless installation reduces the number of crevices where dirt or liquids might accumulate.

Unlike traditional walls, which may require repainting or patching after heavy cleaning, clean panels are resistant to damage from scrubbing, chemicals, or high-pressure washing. This durability ensures the panels maintain their integrity even with daily cleaning routines, reducing long-term maintenance costs.

3. Structural Integrity and Durability

Clean rooms often house heavy equipment, such as manufacturing machinery, lab instruments, or ventilation systems. Clean panels provide the structural strength needed to support these loads while withstanding daily wear. For example, aluminum or stainless steel clean panels resist dents from equipment collisions, while FRP clean panels are flexible enough to withstand minor impacts without cracking.

Additionally, clean panels are designed to maintain their performance in controlled environments. They do not warp or degrade under temperature or humidity fluctuations, which is critical for clean rooms that require stable conditions (e.g., electronics clean rooms with strict temperature controls).

4. Compatibility with Clean Room Systems

Clean panels integrate seamlessly with other clean room components, such as HEPA filters, air handlers, and pass-through chambers. They can be cut or modified to accommodate windows, doors, or utility penetrations (for electrical, plumbing, or HVAC systems) while maintaining airtight seals. This compatibility ensures the entire clean room operates as a cohesive system, minimizing air leakage and particle movement between zones.

For example, clean panels used in ceilings can be fitted with recessed lighting or filter grilles without creating gaps that would compromise air quality. In walls, they can include viewing windows made from tempered glass, allowing visibility while maintaining sterility.

Where Are Clean Panels Used in Clean Rooms?

Clean panels are used throughout clean rooms, from walls and ceilings to partitions and equipment enclosures. Their specific applications vary by industry and clean room type, but they are essential in maintaining contamination control across all sectors.

1. Pharmaceutical and Biotech Clean Rooms

In pharmaceutical and biotech facilities, clean rooms are used for drug manufacturing, vaccine production, and lab research, where even tiny particles or microbes can ruin batches or invalidate results. Clean panels are used extensively here:

- Walls and ceilings: Stainless steel or FRP clean panels line the main walls and ceilings, creating a smooth, non-porous surface that resists chemical disinfection. These panels prevent cross-contamination between production areas and support strict aseptic conditions.

- Isolation rooms: Clean panels form partitions for isolating sensitive processes, such as cell culture or sterile compounding. Their airtight seals prevent airflow between high-risk and low-risk zones.

- Equipment enclosures: Clean panels wrap around manufacturing equipment, such as filling machines or centrifuges, creating easy-to-clean surfaces that protect products from external contamination.

In these environments, clean panels must meet stringent standards, such as FDA regulations, ensuring they do not leach chemicals or shed particles that could contaminate drugs or biological materials.

2. Electronics and Semiconductor Clean Rooms

Electronics clean rooms produce microchips, circuit boards, and other sensitive components, where particles as small as 0.5 microns can damage products. Clean panels play a critical role in maintaining ultra-low particle counts:

- Walls and ceilings: Aluminum composite or PVC clean panels are preferred for their low particle shedding and static resistance. Static control is vital in electronics manufacturing, as static electricity can damage delicate components.

- Partition walls: Clean panels create separate zones for different stages of production (e.g., etching, assembly), preventing cross-contamination between processes.

- Clean benches and workstations: Clean panels line the surfaces of workstations, providing a stable, non-porous area for handling sensitive components. They resist scratches from tools and are easy to clean with anti-static agents.

These clean panels must also withstand frequent cleaning with alcohol-based solutions, which are used to remove oils and particles from surfaces without leaving residues.

3. Healthcare and Medical Clean Rooms

Hospitals and medical facilities use clean rooms for surgeries, sterile storage, and laboratory testing, where infection control is paramount. Clean panels are used in:

- Operating rooms: Stainless steel clean panels cover walls and ceilings, as they are resistant to blood, bodily fluids, and harsh disinfectants. Their smooth surfaces prevent bacterial growth, reducing the risk of surgical site infections.

- Pharmacy clean rooms: Where sterile medications are prepared, clean panels (often FRP or solid surface materials) create a contamination-free environment. They are easy to sanitize between batches, ensuring medication safety.

- Laboratories: Clean panels line walls and work areas in diagnostic labs, protecting samples from external contamination and making it easy to clean up spills of chemicals or biological materials.

In healthcare settings, clean panels must also meet safety standards, such as fire resistance and compatibility with medical-grade disinfectants.

4. Food and Beverage Clean Rooms

Food processing facilities use clean rooms for producing high-risk foods (e.g., ready-to-eat meals, infant formula) or for packaging sterile ingredients. Clean panels help maintain food safety:

- Processing areas: FRP or PVC clean panels line walls and ceilings, resisting moisture, grease, and food particles. They are easy to clean with hot water and food-safe sanitizers, preventing bacterial growth (e.g., Salmonella or E. coli).

- Packaging zones: Clean panels create enclosed spaces for packaging sterile foods, ensuring no contaminants enter during sealing or labeling. Their non-porous surfaces prevent crumbs or liquids from accumulating.

- Storage rooms: Clean panels line walls in cold storage areas, withstanding low temperatures without warping. They resist mold growth in humid environments, protecting food quality.

These clean panels must comply with food safety regulations, such as FDA’s Current Good Manufacturing Practices (CGMP), ensuring they do not leach harmful substances into food.

5. Aerospace and Defense Clean Rooms

Aerospace clean rooms manufacture and assemble sensitive components, such as satellite parts, avionics, or optical systems, where even minor contamination can cause equipment failure. Clean panels are used in:

- Assembly areas: Aluminum or stainless steel clean panels create dust-free environments for assembling precision parts. Their durability withstands the heavy equipment and tools used in aerospace manufacturing.

- Testing chambers: Clean panels line environmental testing chambers, which simulate extreme conditions (e.g., high pressure, temperature cycles). The panels resist corrosion and maintain integrity under these stressors.

- Clean storage areas: For storing sensitive components, clean panels prevent dust accumulation and protect parts from humidity or chemical exposure.

In these settings, clean panels often have specialized features, such as electromagnetic interference (EMI) shielding, to protect electronic components from external signals.

Benefits of Using Clean Panels in Clean Rooms

The use of clean panels in clean rooms offers numerous advantages that support operational efficiency, safety, and compliance:

- Reduced contamination risks: Their non-porous, low-shedding surfaces minimize particle and microbial buildup, lowering the chance of product defects or failed tests.

- Lower maintenance costs: Clean panels resist damage from cleaning and wear, reducing the need for frequent repairs or replacements compared to traditional materials.

- Faster cleaning routines: Smooth, seamless surfaces allow quick disinfection, saving time and labor in busy clean room operations.

- Compliance with standards: Clean panels meet industry regulations (e.g., ISO, FDA, GMP), helping facilities pass inspections and maintain certifications.

- Flexibility: They can be customized to fit unique clean room layouts, with options for windows, doors, or utility access without compromising integrity.

FAQ

What materials are clean panels made of?

Clean panels are typically made from outer layers of stainless steel, aluminum, PVC, or FRP, with cores of foam, mineral fiber, or plywood. The choice depends on the clean room’s needs, such as chemical resistance, static control, or durability.

How do clean panels differ from regular wall panels?

Regular wall panels (e.g., drywall, painted wood) are porous, shed particles, and may degrade with harsh cleaning. Clean panels are non-porous, low-shedding, and resistant to chemicals and impacts, making them suitable for controlled environments.

Can clean panels be reused in different clean room setups?

Yes, many clean panels are modular and can be disassembled, moved, and reinstalled in new layouts. This flexibility is useful for facilities that reconfigure clean rooms for different projects.

How often do clean panels need to be replaced in clean rooms?

With proper maintenance, clean panels can last 10–20 years. Their lifespan depends on material (e.g., stainless steel lasts longer than PVC) and usage intensity (e.g., high-traffic areas may wear faster).

Are clean panels fire-resistant?

Many clean panels are fire-resistant, especially those with mineral cores or metal outer layers. Manufacturers provide fire ratings (e.g., ASTM E84) to ensure compliance with safety codes in clean rooms.