Optimizing Airflow Management in Modular Clean Rooms

Reducing Air Change Rates Without Compromising Cleanliness

Getting the right balance between air changes and keeping things clean in modular cleanrooms really affects how much energy gets used. When there are too many air changes happening, that just wastes power needlessly. Facility managers who install accurate measuring devices like Coriolis Flow Meters can actually track those airflow numbers precisely. Then they tweak their HVAC systems on the fly so they save energy but don't let the cleanliness drop below acceptable levels. The IEC guidelines basically say we should check our air change rates against what the ISO Classes demand for different environments. Following this approach helps facilities stay within regulations while cutting down on wasted air changes. Most importantly, sticking to these standards means real money savings over time without sacrificing safety or meeting all those regulatory requirements that come with running a cleanroom operation.

Implementing Low Section Wind Velocity Design

When setting up airflow systems for modular clean rooms, keeping section wind velocities low really makes a difference in how efficient everything runs and how long equipment lasts. Most engineers now rely on Computational Fluid Dynamics or CFD models to figure out where air moves around and tweak designs so those high speed zones don't form in important spots. Adding adjustable air diffusers throughout the system helps spread filtered air evenly across the space, which means no more annoying hotspots that mess with sensitive processes. The lower wind speeds matter because they put less strain on all the machinery and supporting structures inside the room. We've seen this firsthand in several facilities where maintenance costs dropped significantly after redesigning for better airflow management. Cleanroom managers who factor these details into their planning typically find themselves with systems that perform well while standing the test of time much better than those rushed installations that cut corners on airflow specs.

Balancing Airflow for ISO Class Compliance

Getting the right balance of air movement matters a lot when it comes to meeting ISO Class standards in cleanrooms. When there are differences in how much air flows through various parts of the room, this creates real problems with contamination control. That's why many facilities install flow measuring equipment these days. These tools let technicians check what's happening with air currents throughout different areas and make adjustments on the fly to keep everything within those strict ISO limits. Following rules set out by standards bodies like EN 14644 isn't just good practice either it actually makes sense from an energy standpoint too. Proper airflow management protects sensitive processes inside the cleanroom while cutting down on wasted power at the same time. Most manufacturers find that sticking to these guidelines ends up saving money long term despite the initial investment costs involved.

Enhancing Motor and Equipment Efficiency

Upgrading to High-Efficiency Motors

High efficiency motors such as IE3 and IE4 models can cut energy consumption by around 30 percent in industrial settings. The basic idea is simple enough these motors produce the same amount of power while consuming far less electricity, which makes them an attractive option for manufacturers wanting to trim down their operational expenses. Some factories reported cutting their monthly electric bills by thousands after upgrading to these newer motor technologies. Getting the right size motor matters a lot too. Motors that are either oversized or undersized waste energy because they don't match what the equipment actually needs to run properly. When companies take the time to calculate exactly what kind of motor power their machinery requires day to day, they find that those initial costs for high efficiency units start paying off pretty quickly through reduced energy consumption.

Utilizing Variable Speed Drives (VSDs)

VSDs, or Variable Speed Drives, let companies control motor speeds according to what's actually needed at any given moment. When motors run slower than full speed, they consume far less power. According to several industry studies, implementing VSD tech in different settings often leads to big drops in energy bills, sometimes cutting usage by half or more. Before installing these systems though, manufacturers should check if their current machinery will work well with VSDs. Getting this right from the start makes all the difference. The energy savings kick in pretty quickly after installation too, boosting overall efficiency while avoiding costly system replacements or production downtime.

Regular Maintenance for Peak Performance

Creating a solid maintenance plan really matters if we want our equipment to stay in top shape. The routine work includes checking things over regularly, giving them a good clean, and making necessary tweaks so everything keeps running without hiccups. Some research points to around a quarter reduction in energy usage when companies get ahead of maintenance needs, which means longer life for machines and fewer expensive repairs down the road. These days many facilities are installing automated monitoring tech that sends warnings about possible trouble spots before real damage happens. Getting these systems up and running helps spot problems sooner rather than later, so operations stay smooth and companies actually hit those energy saving targets they set themselves.

Advanced Cooling Strategies for Energy Savings

Dual-Temperature Cooling Loop Systems

Dual temperature cooling loops represent a smarter way to handle cooling demands by running different temps through various parts of the system. What makes this setup work so well is that some components get cooled down more aggressively while others stay at standard levels, leading to better overall performance across the board. These kinds of systems really shine in modular clean room environments where keeping temperatures spot on matters a lot for meeting those tough industry specs. Companies switching from old school single loop setups often see pretty decent energy bill reductions too. Being able to dial in exactly what each area needs instead of blasting everything with full power cuts down on wasted energy, making operations cheaper to run and generally easier to manage day to day.

Free Cooling Techniques for Modular Setups

Free cooling works by bringing in outside air through existing HVAC systems when weather conditions are good enough to cut down on electricity use. Facilities can actually chill their spaces using the cold air from outdoors, particularly when temperatures drop at night or when humidity stays low. Research indicates that implementing these techniques in pharmaceutical clean rooms alone can save anywhere between 30% to 50% on annual cooling expenses. The math behind ROI calculations matters quite a bit here since installation might run into several thousand dollars upfront but pays itself back over time through reduced utility bills. Many industrial sites looking to green their operations find free cooling to be one of those no-brainer solutions that delivers both environmental benefits and real money savings month after month.

Optimizing Chilled Water Supply Temperatures

Getting the right temperature for chilled water supply makes a big difference when it comes to making cooling systems work better and saving energy in clean room environments. When facilities keep these temps just right, they get much better cooling results that actually match what their operations need in terms of cooling load and air quality standards. The industry has all sorts of guidelines about what temperatures should be for maximum efficiency, which helps cut down on wasted energy. Looking at real world examples shows how adjusting chilled water temperatures properly leads to significant energy savings and better overall performance. For businesses concerned about both their bottom line and environmental impact, focusing on these temperature adjustments pays off in multiple ways, helping them run cleaner while spending less on power bills.

Sustainable Heat Recovery Systems

Capturing Waste Heat from HVAC Systems

Grabbing waste heat from HVAC systems actually works pretty well when trying to boost energy efficiency, especially in factories and manufacturing plants where heating and cooling run constantly. These recovery systems basically snatch up all that extra heat that normally just gets wasted and put it to good use elsewhere, like warming up incoming air or water before it hits the main system. According to real world data, companies saving money on their energy bills after installing these systems isn't uncommon at all. Take what the US Department of Energy found last year showing around 30% reductions in some industrial settings. There are several options out there today for capturing this wasted heat. Air to air exchangers remain popular in many facilities while heat pumps offer another solution, though they tend to cost more upfront. Thermal wheels also get used quite a bit but perform best under certain conditions. What works best really depends on what kind of operation needs the heat recovered and how much budget is available for installation.

Integrating Heat Exchangers for Energy Reuse

Adding heat exchangers to clean room systems represents one of the smarter ways facilities can cut down on energy waste. Temperature control remains absolutely critical in many manufacturing environments, after all. Different types work better depending on the situation – plate, shell and tube units tend to handle certain applications well, while rotary models might suit others. When installing these systems, technicians need to focus on getting good thermal contact between components without compromising against requirements from regulatory bodies like ISO or GMP standards. Real world data shows pretty impressive results too; some manufacturers saw their energy bills drop by around 15% after retrofitting with proper heat exchange technology. Of course, making this work long term requires not just smart installation but regular checks and maintenance too, since even small issues can quickly undermine those efficiency gains over time.

Preheating Outside Air with Recovered Energy

Capturing waste heat to warm up incoming air represents one of those smart tricks that can really cut down on energy bills. When systems tap into heat generated from exhaust gases or other industrial processes, they basically get free warmth for the air going into HVAC units. This means less reliance on furnaces or boilers for extra heating. Many factories have reported cutting their winter heating expenses by over 30% after implementing such systems. The environmental benefits are just as impressive too. By reducing dependence on fossil fuel-based heating methods, these setups help shrink carbon emissions across operations, something that fits nicely with current green initiatives worldwide. From a business standpoint, getting both lower operating costs and a smaller ecological impact makes this technique worth considering for any facility looking to improve efficiency without breaking the bank.

Leveraging Modular Design for Efficiency

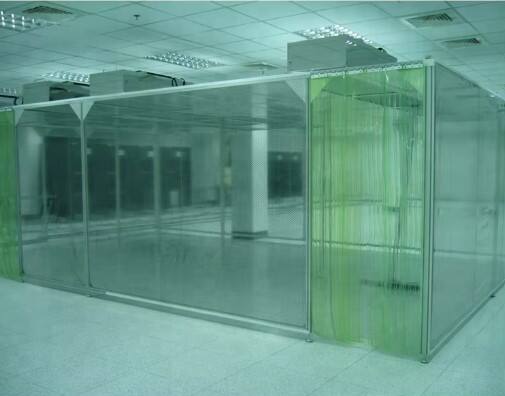

Scalability and Flexibility in Clean Room Layouts

Clean rooms built with modular designs offer real advantages when it comes to scaling operations and staying flexible. When market conditions change or production needs shift, businesses don't have to tear everything apart just to adjust. Companies simply add or remove modules as needed, keeping things running smoothly whether they're producing small batches or ramping up for large orders. The pharmaceutical industry has seen this work particularly well, where space constraints often limit growth options. Modular setups let them make better use of available floor space while avoiding expensive rebuilds. What's more, these systems tend to save money on energy costs too. Traditional clean rooms consume power regardless of actual usage levels, but modular ones only require energy for active sections during expansion phases or when scaling back operations, which makes financial sense for manufacturers looking to cut long term expenses.

Prefabricated Components for Reduced Energy Leakage

Using prefabricated parts for building clean rooms makes a big difference when it comes to keeping things insulated and cutting down on wasted energy. These factory-made components snap together really well, forming tight seals that stop heat from escaping. Traditional construction often leaves small gaps between sections or needs extra sealing material just to reach basic insulation standards. Studies have found that these prefabricated setups cut energy loss dramatically. One report showed energy bills dropping around 20% for facilities switching from standard construction to prefabricated systems. Better thermal control means real money saved over time, which is why more companies are turning to prefabricated solutions for their clean room needs instead of sticking with old school methods.

Streamlined HVAC Integration in Modular Systems

Putting HVAC systems into modular clean rooms makes a big difference when it comes to saving energy and cutting down on running expenses. When the heating, ventilation and air conditioning work together smoothly with the clean room setup, we get better airflow control and stable temperatures throughout the space. Real world installations have shown energy bills dropping by as much as 30% after proper integration. Looking ahead, manufacturers are already working on next generation HVAC solutions that promise even greater efficiency gains. These new approaches aim to meet stricter regulations without breaking the bank, though there are still challenges to overcome before widespread adoption becomes reality. Sustainability remains at the forefront of development efforts across the industry.

Smart Monitoring and Adaptive Controls

Real-Time Particle Counting for Dynamic Adjustments

Keeping track of airborne particles in real time helps maintain good air quality inside cleanrooms because it lets operators monitor and tweak systems whenever something goes off track. These particle counters basically spot and count dust and other tiny stuff floating around, so engineers can quickly fix ventilation or filter problems before they become bigger issues that mess up cleanroom specs. Research shows cleaner environments result from these monitoring systems. Some places actually cut down on contamination by more than half after implementing them. Adding IoT tech makes things even better since it collects data constantly and analyzes it on the fly. This means equipment runs smarter too, adjusting itself based on what's happening in the environment rather than wasting power all day long.

Automated Temperature and Humidity Regulation

Cleanrooms rely heavily on automated systems to keep temperature and humidity at just the right levels, creating better conditions while also cutting down on energy bills. These systems work through sensors and controls that help maintain stable environments inside these sensitive spaces, something crucial for keeping products intact and avoiding production hiccups. Studies show that going automated really pays off in terms of energy efficiency too many facilities report saving around 30% on their electricity costs after implementing these systems. The latest tech improvements, including things like machine learning, are taking cleanroom management even further forward. With smarter algorithms now able to adjust settings based on real time conditions, operators get much better control over their environment without constant manual intervention.

Energy Dashboards for Continuous Improvement

Energy dashboards serve as essential resources that give real insight into how power gets consumed inside cleanrooms, helping facility managers tweak their operations while keeping expenses under control. When companies track their actual energy usage through these systems, they often spot areas where money is being wasted and can switch to greener methods instead. Take some manufacturers who discovered around 20% extra energy spend using dashboard data - fixing those issues led to significant savings on utility bills. What's next? We're seeing improvements in monitoring tech all the time. Expect to see more AI features coming onboard soon, along with predictive maintenance capabilities. These upgrades should help cleanroom operators make smarter choices about energy management long before problems arise, making facilities run smoother without breaking the bank.

FAQ

What is the importance of airflow management in modular clean rooms?

Efficient airflow management in modular clean rooms is crucial for maintaining cleanliness and energy efficiency, ultimately ensuring compliance with ISO Class requirements and reducing unnecessary energy consumption.

How can energy savings be achieved by using high-efficiency motors?

High-efficiency motors such as IE3 or IE4 can reduce energy consumption by up to 30%. Properly sizing these motors can prevent energy losses, making them a worthwhile investment over time.

What are the benefits of integrating heat exchangers in clean rooms?

Heat exchangers help maximize energy conservation by maintaining stringent temperature controls, improving energy efficiency, and reducing operational costs through effective energy reuse.

How do modular designs improve energy efficiency in clean rooms?

Modular designs enhance scalability and flexibility, reduce energy leakage through prefabricated components, and allow for efficient HVAC integration, all contributing to lower energy consumption and operational costs.

What role do smart monitoring and controls play in clean room efficiency?

Smart monitoring and adaptive controls, such as real-time particle counting and automated systems, ensure optimal environmental conditions and energy efficiency by providing real-time adjustments and insights into energy use.