Understanding Air Showers and Their Role in Clean Room Contamination Control

Air showers basically work as powerful air filtration units installed at the doorways of cleanrooms and other controlled spaces. These systems blast out high speed air to knock off dust, hair, and other tiny particles from people's clothes or tools before they go inside. For manufacturing sectors dealing with sensitive products like semiconductors or pharmaceuticals, this kind of setup becomes absolutely necessary for keeping contaminants out. Without proper decontamination steps at entry points, even microscopic particles can ruin entire batches of expensive goods.

How Air Showers Work

Air showers operate by blowing high-speed, HEPA- or ULPA-filtered air through strategically placed nozzles. As a person or object enters the chamber, motion sensors or door interlocks activate the air jets. These jets dislodge and capture dust, fibers, and other contaminants from clothing or surfaces.

The air is then recirculated through filtration systems, ensuring that particles are trapped and do not reenter the environment. This cycle continues for 15 to 45 seconds, depending on the cleanliness requirements of the facility.

The dual-door interlock mechanism ensures that the clean room remains sealed off during the air shower cycle, preventing unfiltered air from entering. Only once the decontamination process is complete will the inner door unlock, allowing entry.

Design Features That Maximize Efficiency

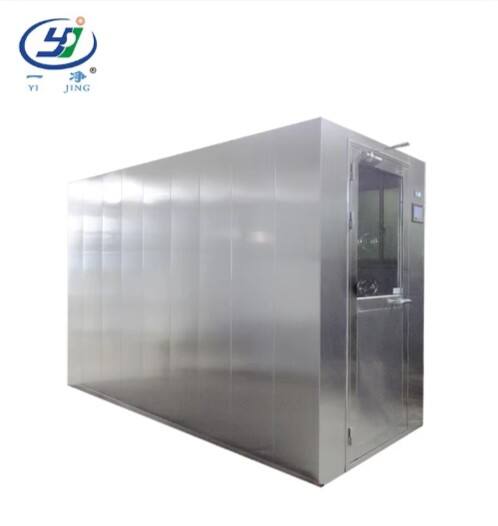

Air showers come in various configurations, including straight-through, L-shaped, or tunnel designs, depending on spatial constraints and traffic volume. The interior is often constructed from stainless steel or coated steel panels, designed for easy cleaning and minimal particle shedding.

Adjustable nozzles allow for targeted airflow, and programmable control systems let operators tailor cycle times and fan speeds. Some advanced systems include ionizers to neutralize static electricity, which can attract airborne particles.

The integration of sensor-based activation and automated door locking enhances both usability and contamination control. These design choices ensure that the air shower performs consistently, regardless of user behavior or frequency of use.

Benefits of Air Showers for Clean Room Integrity

Minimizing Contaminant Entry

The primary function of an air shower is to reduce the particulate load entering a clean room. Even with gowning protocols, human operators carry skin flakes, textile fibers, and dust particles that can compromise controlled environments.

By placing an air shower between gowning areas and the clean room, facilities can intercept contaminants before they reach critical zones. This helps maintain ISO clean room classifications and ensures compliance with regulatory requirements.

In facilities dealing with sensitive components like semiconductors or pharmaceuticals, even microscopic particles can result in product defects or safety risks. Air showers act as the final line of defense in a layered contamination control strategy.

Enhancing Operational Efficiency

Air showers streamline entry procedures by replacing more manual cleaning methods. Instead of relying solely on gowning and inspection, the air shower provides a standardized and automatic decontamination step.

This consistency improves throughput and reduces human error, especially in high-traffic environments. Operators can enter and exit clean rooms more quickly without compromising on cleanliness standards.

Furthermore, air showers can be integrated with access control systems, restricting entry only to authorized personnel who have completed the full air shower cycle.

Reducing Clean Room Maintenance Costs

Clean rooms require significant investment in air filtration, HVAC systems, and regular maintenance to remain compliant. Air showers contribute to cost savings by reducing the volume of contaminants introduced into the environment.

Fewer contaminants mean less frequent filter changes, reduced equipment downtime, and lower risk of product contamination. Over time, these savings add up, especially in facilities with high personnel traffic.

Industries That Benefit Most from Air Showers

Semiconductor and Electronics Manufacturing

In microelectronics, airborne particles can damage wafers or disrupt circuit paths. Air showers ensure that technicians entering the clean room are free of dust or static-charged debris that could interfere with production.

Pharmaceutical and Biotechnology Facilities

For these industries, contamination isnât just a quality issueâitâs a regulatory one. Air showers support sterile manufacturing environments by acting as an additional barrier between gowning areas and critical zones, reducing the risk of microbial or particulate intrusion.

Aerospace and Precision Engineering

Components in these sectors often require defect-free assembly in controlled conditions. Air showers help maintain the cleanliness required for bonding, coating, and assembly processes involving sensitive materials.

Food and Beverage Processing

Though less common than in high-tech industries, air showers are increasingly used in food processing areas to limit bacterial and particulate contamination, especially in zones with open product exposure.

Installation and Maintenance Considerations

Space and Workflow Integration

Air showers must be placed strategically to align with personnel movement and clean room layout. Inadequate positioning can create bottlenecks or encourage non-compliance. Designing entry areas with sufficient space for gowning and air shower use is key.

Facilities should also assess whether personnel or equipmentâor bothâwill be using the air showers, as this affects chamber dimensions and airflow requirements.

Routine Maintenance

Like any mechanical system, air showers require regular upkeep to maintain performance. HEPA filters must be inspected and replaced on schedule. Fans, nozzles, and sensors should be cleaned and calibrated routinely.

Maintenance schedules should align with usage levels. Facilities with multiple shifts or high throughput may require more frequent servicing to ensure uninterrupted performance.

Employee Training and SOP Integration

Employees must be trained on proper air shower use, including how to stand during the cycle, rotate for full coverage, and wait until the cycle ends. Standard operating procedures should emphasize that skipping the air shower or exiting early compromises clean room integrity.

Signage, access control, and occasional audits can reinforce correct usage.

Conclusion

Air showers are a vital component in any contamination control strategy for clean rooms and controlled environments. By using high-velocity, filtered air to remove particles before personnel or equipment enter critical zones, air showers help maintain ISO classifications, reduce product defects, and support regulatory compliance.

Selecting, installing, and maintaining the right air shower systemâtailored to your facilityâs layout and risk profileâcan significantly enhance operational efficiency and product quality in industries where cleanliness is non-negotiable.

FAQ

Can air showers be used for equipment as well as personnel?

Yes, there are larger air shower chambers designed specifically for carts, trolleys, or sensitive equipment that must enter clean rooms without introducing contaminants.

How long does a typical air shower cycle last?

Most air shower cycles last between 15 to 45 seconds, depending on industry protocols and equipment settings. Customizable timers allow for adaptation to specific facility needs.

Are air showers required for ISO Class 7 or lower clean rooms?

While not always required by regulation, air showers are often recommended for ISO Class 7 and cleaner environments, especially in sectors where contamination poses high risk.

What type of filtration do air showers use?

Most air showers use HEPA filters capable of trapping particles as small as 0.3 microns. Some advanced models use ULPA filters for even finer filtration in ultra-clean environments.