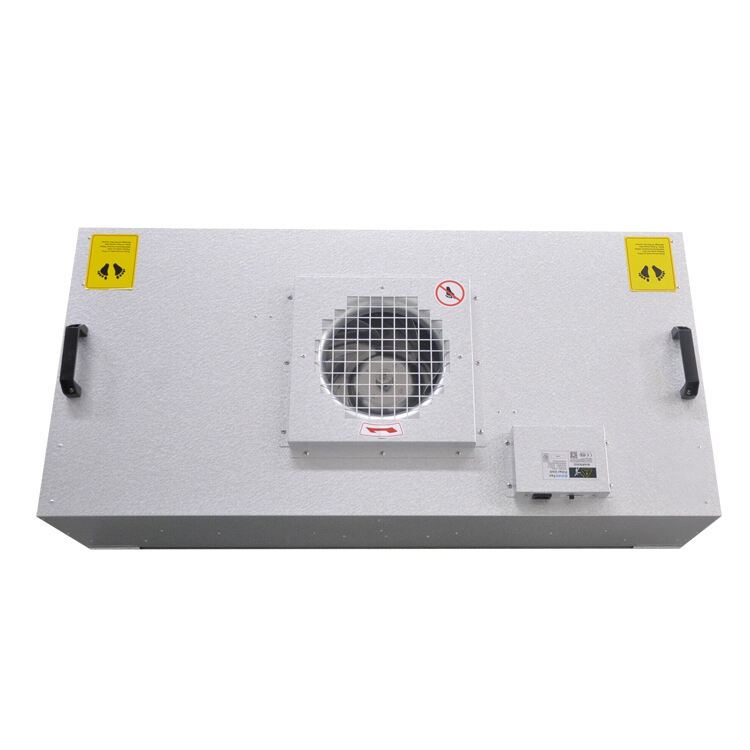

ventilator filter unit

A ventilator filter unit is a critical component in respiratory care systems, designed to ensure clean and safe air delivery to patients requiring mechanical ventilation. This sophisticated device combines multiple filtration layers to effectively remove harmful particles, bacteria, and viruses from both inspired and expired air. The unit typically incorporates high-efficiency particulate air (HEPA) technology, capable of capturing particles as small as 0.3 microns with 99.97% efficiency. Modern ventilator filter units also feature heat and moisture exchanging capabilities, helping to maintain optimal humidity levels in the breathing circuit while preventing bacterial and viral contamination. These units are engineered with precise flow resistance specifications to ensure minimal impact on breathing effort while maximizing filtration effectiveness. The design includes specialized ports for gas sampling and pressure monitoring, enabling healthcare providers to maintain accurate patient monitoring. Advanced models incorporate smart indicators for filter lifecycle management and feature quick-connect mechanisms for safe and efficient filter changes. These units are essential in both hospital and emergency care settings, providing crucial protection for both patients and healthcare workers while maintaining optimal ventilation performance.