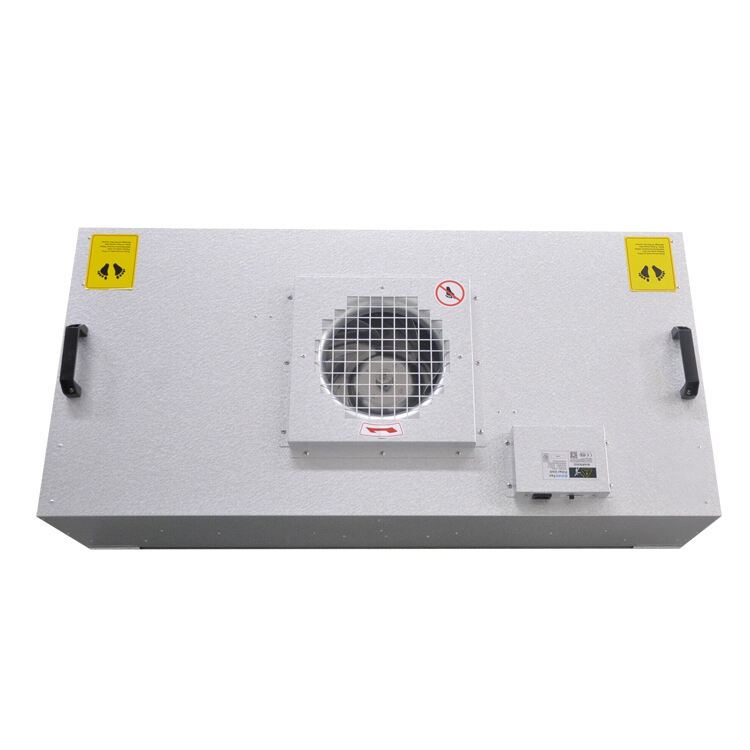

ffu unit

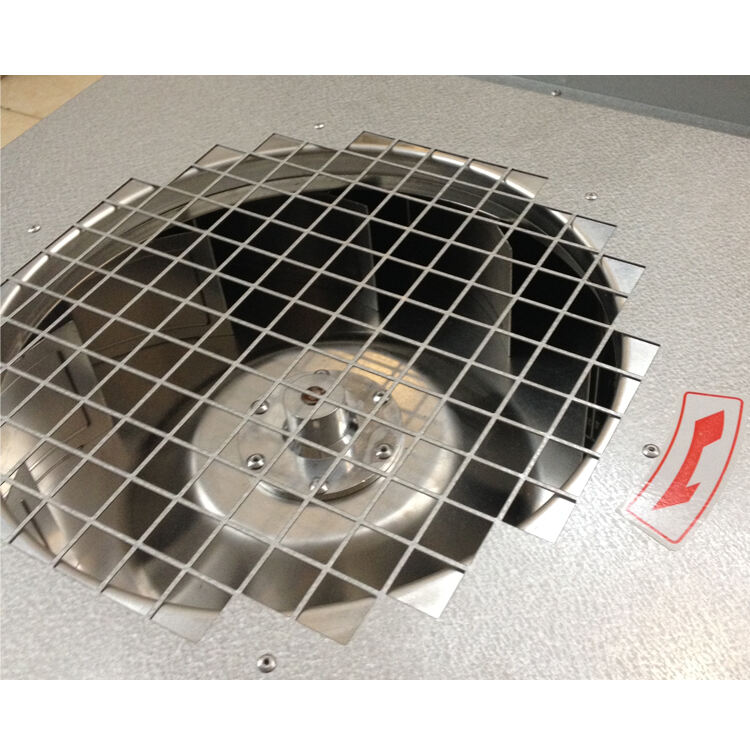

The FFU (Fan Filter Unit) is an advanced air purification system that combines a high-efficiency fan with a HEPA filter in a single, compact unit. This innovative device plays a crucial role in maintaining clean room environments and controlled atmospheric conditions across various industries. The unit operates by drawing air through its motorized fan system, passing it through multiple filtration stages that effectively remove particulates down to 0.3 microns in size. With its sophisticated electronic controls, the FFU unit allows precise adjustment of airflow rates and pressure differentials, ensuring optimal air quality management. The system incorporates smart monitoring capabilities that provide real-time feedback on filter status, air velocity, and overall performance metrics. Modern FFU units feature energy-efficient EC motors that significantly reduce power consumption while maintaining consistent performance levels. These units are designed for ceiling-mounted installation, creating a uniform, downward laminar airflow that prevents cross-contamination and maintains cleanliness standards. The modular nature of FFU systems allows for scalable solutions, making them suitable for both small laboratory spaces and large-scale industrial applications.