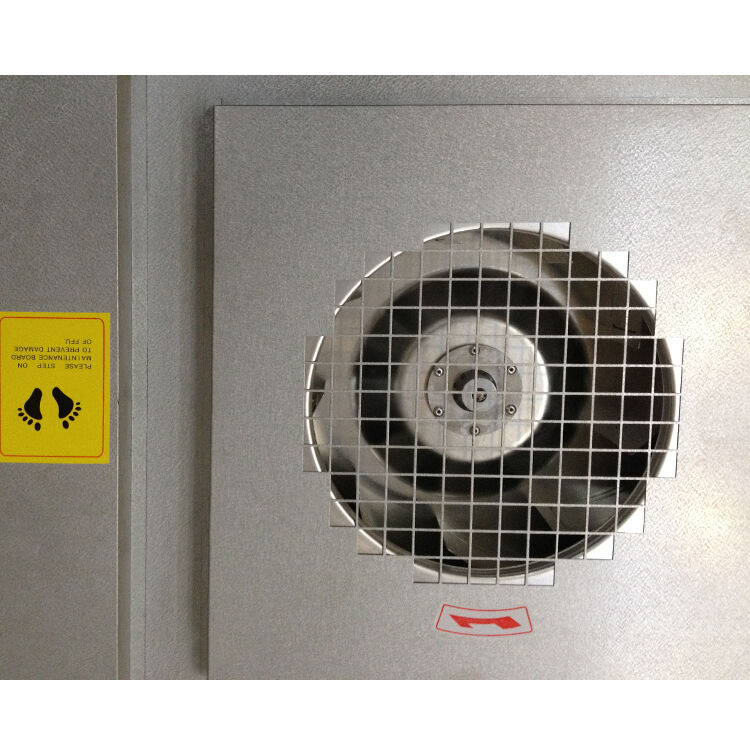

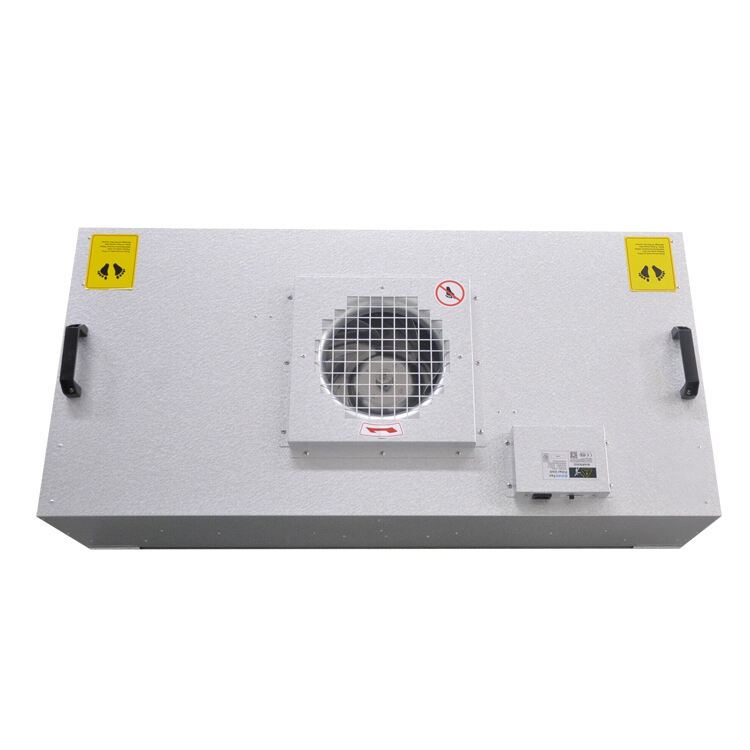

ffu clean room

The FFU Clean Room represents a pinnacle of contamination control technology, integrating advanced Fan Filter Units (FFU) to maintain pristine environmental conditions. This sophisticated system combines HEPA filtration technology with precision airflow management to create and maintain controlled environments essential for various industries. The clean room's design incorporates a modular ceiling grid system where FFUs are strategically positioned to ensure uniform air distribution and optimal particle removal. Operating on the principle of laminar airflow, these units continuously filter and circulate air to maintain specified cleanliness levels, typically achieving ISO classifications from Class 3 to Class 8. The system's intelligent control mechanisms allow for real-time monitoring and adjustment of air pressure, temperature, and humidity levels. Each FFU functions independently, providing redundancy and ensuring system reliability. The clean room's construction features non-shedding materials, seamless wall panels, and specialized flooring to prevent particle generation and accumulation. This comprehensive approach to contamination control makes FFU clean rooms indispensable in semiconductor manufacturing, pharmaceutical production, medical device assembly, and other precision industries requiring stringent environmental control.