Essential Guidelines for Air Handling Unit Performance

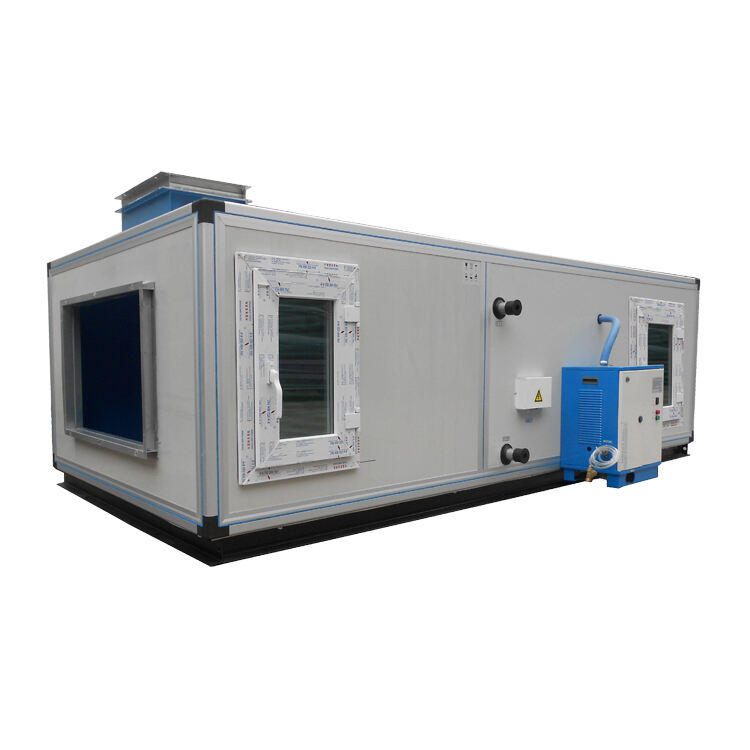

Air handling units (AHUs) are the backbone of any building's HVAC system, responsible for maintaining comfortable indoor environments and ensuring proper ventilation. Effective air handling unit maintenance is crucial for optimal performance, energy efficiency, and longevity of the equipment. A well-maintained AHU not only provides consistent airflow but also contributes to better indoor air quality and reduced operational costs.

Building managers and facility operators must understand that regular maintenance isn't just about preventing breakdowns - it's about maintaining peak performance and ensuring occupant comfort. This comprehensive guide will explore the essential aspects of air handling unit maintenance, from routine checks to advanced preventive measures.

Core Components of Air Handling Unit Systems

Critical Mechanical Elements

The heart of any air handling unit consists of several mechanical components that work in harmony. The primary elements include fans, motors, belts, and bearings. These components require regular air handling unit maintenance to prevent wear and tear. Fan assemblies should be inspected monthly for proper alignment, while motor bearings need regular lubrication according to manufacturer specifications.

Belt tension and condition are particularly crucial as they directly impact airflow efficiency. Loose or worn belts can reduce fan performance and increase energy consumption. Regular inspection of these components helps identify potential issues before they escalate into major problems.

Filtration Systems and Their Impact

Filtration systems play a vital role in maintaining air quality and protecting downstream components. Different levels of filters, from pre-filters to HEPA filters, require specific maintenance schedules. Air handling unit maintenance for filtration systems includes regular inspection, cleaning, and replacement of filters based on pressure drop readings and visual inspection.

Clean filters not only ensure better air quality but also maintain proper airflow through the system. Clogged or dirty filters force the unit to work harder, increasing energy consumption and potentially damaging other components.

Preventive Maintenance Strategies

Scheduled Inspection Protocols

Implementing a structured inspection protocol is fundamental to effective air handling unit maintenance. This should include daily visual checks, weekly operational assessments, and monthly comprehensive inspections. During these inspections, technicians should examine all accessible components, looking for signs of wear, unusual noise, or vibration.

Documentation of these inspections helps track system performance over time and can indicate when components are beginning to deteriorate. This proactive approach allows facility managers to address issues before they lead to system failure.

Cleaning and Sanitization Procedures

Regular cleaning is a crucial aspect of air handling unit maintenance. Cooling coils, drain pans, and ductwork must be kept free from dirt, debris, and biological growth. A proper cleaning schedule helps prevent the buildup of contaminants that can restrict airflow and reduce system efficiency.

Sanitization procedures should be performed periodically, especially in healthcare facilities or other sensitive environments. This includes using appropriate cleaning agents and ensuring proper drainage of cleaning solutions to prevent moisture-related issues.

Advanced Maintenance Techniques

Performance Monitoring Systems

Modern air handling unit maintenance increasingly relies on sophisticated monitoring systems. Building automation systems can track key performance indicators such as airflow rates, pressure differentials, and energy consumption. This data helps identify trends and potential problems before they become critical.

Implementing sensors and monitoring equipment allows for real-time tracking of system performance. This technology enables predictive maintenance approaches, helping facility managers optimize maintenance schedules and reduce operational costs.

Energy Efficiency Optimization

Regular air handling unit maintenance directly impacts energy efficiency. Optimizing damper operations, ensuring proper refrigerant charge, and maintaining clean heat exchange surfaces all contribute to reduced energy consumption. Regular testing and balancing of the system ensure it operates at peak efficiency.

Energy audits should be conducted periodically to identify opportunities for improvement. This might include upgrading to more efficient components or implementing advanced control strategies to optimize system performance.

Troubleshooting Common Issues

Airflow Problems and Solutions

Common airflow issues often stem from component failures or maintenance oversights. Regular air handling unit maintenance helps identify problems such as blocked filters, damaged belts, or malfunctioning dampers. Understanding the relationship between different components helps technicians quickly diagnose and resolve airflow problems.

When troubleshooting airflow issues, it's essential to follow a systematic approach. This includes checking filter condition, verifying fan operation, and examining ductwork for potential restrictions or leaks.

System Performance Analysis

Regular performance analysis is crucial for maintaining optimal operation. This includes measuring and recording key parameters such as supply and return air temperatures, humidity levels, and static pressure readings. These measurements help identify system inefficiencies and guide maintenance decisions.

Trending this data over time provides valuable insights into system behavior and helps predict potential failures before they occur. This proactive approach to air handling unit maintenance reduces downtime and extends equipment life.

Frequently Asked Questions

How often should air filters be replaced in an air handling unit?

The frequency of filter replacement depends on several factors, including the environment, usage patterns, and filter type. Generally, pre-filters should be checked monthly and replaced every 3-4 months, while final filters might last 6-12 months. However, pressure drop readings across the filter bank should guide actual replacement intervals.

What are the signs that an air handling unit needs immediate maintenance?

Key indicators include unusual noise or vibration, reduced airflow, inconsistent temperature control, increased energy consumption, and unusual odors. If you notice any of these signs, immediate air handling unit maintenance is recommended to prevent system failure and ensure optimal performance.

How can regular maintenance improve energy efficiency?

Regular air handling unit maintenance improves energy efficiency by ensuring clean heat exchange surfaces, proper belt tension, optimal refrigerant charge, and efficient motor operation. Well-maintained units require less energy to operate, resulting in lower utility costs and reduced environmental impact.

What role does humidity control play in air handling unit maintenance?

Proper humidity control is essential for comfort and equipment longevity. Regular maintenance ensures proper operation of humidity control components, preventing issues like condensation, mold growth, and excessive moisture that can damage the system and affect indoor air quality.