Understanding the Revolutionary Impact of Modular Clean Panels in Modern Facilities

Modular clean panels have transformed the way industries approach controlled environments and cleanroom construction. These innovative building components represent a significant leap forward in creating sterile, controlled spaces across pharmaceutical, semiconductor, biotechnology, and healthcare sectors. As facilities face increasing demands for cleanliness and contamination control, modular clean panels emerge as a cornerstone solution that combines flexibility, efficiency, and superior performance.

The evolution of cleanroom technology has led to the development of sophisticated modular clean panels that offer unprecedented control over particulate contamination while providing remarkable adaptability to changing facility needs. These advanced systems have become indispensable in maintaining the strict environmental standards required by modern industrial and research operations.

Core Advantages of Modular Clean Panel Systems

Enhanced Installation Efficiency and Cost-Effectiveness

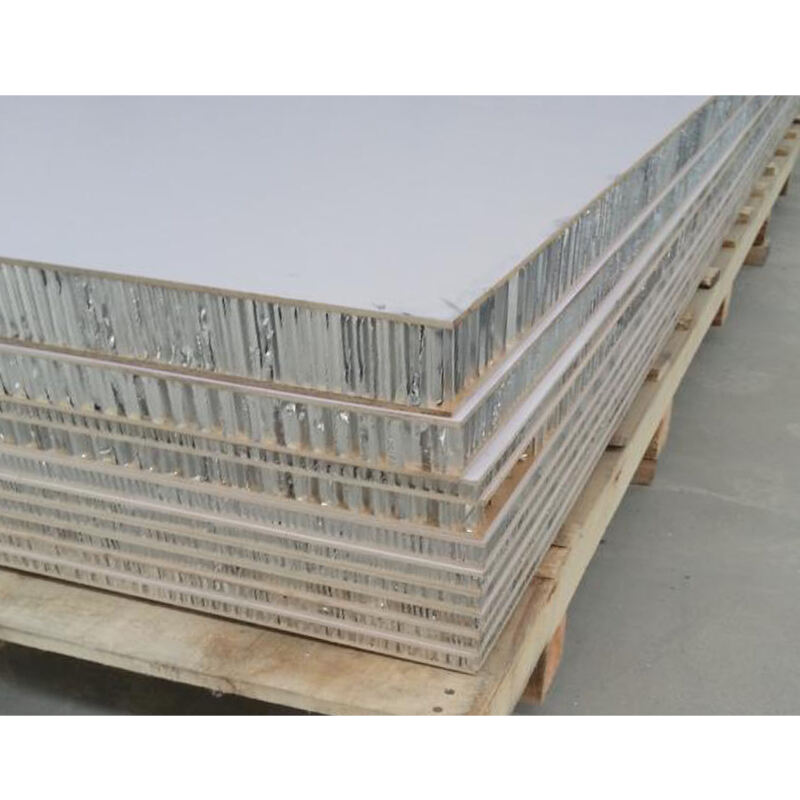

One of the most compelling benefits of modular clean panels lies in their streamlined installation process. Unlike traditional construction methods that require extensive on-site work and coordination between multiple trades, modular clean panels arrive pre-engineered and ready for immediate installation. This approach significantly reduces construction timelines and associated labor costs, often resulting in savings of 30-40% compared to conventional building methods.

The cost benefits extend beyond initial installation. Modular clean panels are designed for long-term durability, requiring minimal maintenance and offering excellent value over their operational lifetime. Their factory-controlled manufacturing ensures consistent quality and eliminates many of the variables that can lead to costly repairs or replacements in traditional constructions.

Superior Cleanliness and Contamination Control

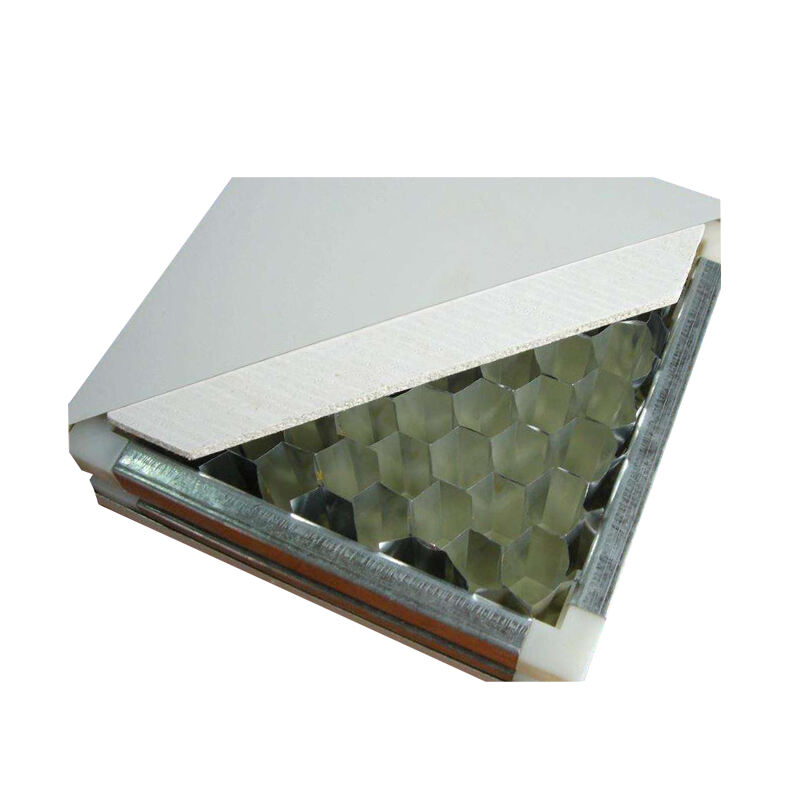

The primary function of modular clean panels is to maintain stringent cleanliness standards, and they excel in this regard. These panels feature non-porous, smooth surfaces that prevent particle accumulation and facilitate easy cleaning. Their sealed joints and specialized coating technologies create an impermeable barrier against contaminants, making them ideal for environments that must meet strict regulatory requirements.

Advanced modular clean panels incorporate antimicrobial properties and specialized surface treatments that actively resist bacterial growth and chemical degradation. This enhanced protection is crucial for pharmaceutical manufacturing, medical device production, and other sensitive applications where maintaining sterility is paramount.

Design Flexibility and Customization Options

Adaptable Configuration Capabilities

Modern modular clean panels offer unprecedented flexibility in cleanroom design and layout. Their modular nature allows for easy reconfiguration as operational needs change, enabling facilities to adapt their clean spaces without undertaking major construction projects. This adaptability proves invaluable as companies scale operations or modify production processes.

The versatility of these panels extends to their integration with various facility systems. They can accommodate different door types, windows, pass-through chambers, and utility connections while maintaining their essential cleanroom properties. This adaptability ensures that facilities can create highly functional spaces that meet specific operational requirements.

Aesthetic and Functional Customization

Beyond their practical benefits, modular clean panels offer extensive customization options in terms of appearance and functionality. Facilities can choose from various surface finishes, colors, and textures to create environments that align with their brand identity while maintaining required cleanliness standards. This attention to aesthetics can contribute to a more pleasant working environment and improved employee satisfaction.

The panels can also be customized with specialized coatings or materials to meet specific industry requirements, such as static dissipative properties for electronics manufacturing or chemical resistance for pharmaceutical applications. This level of customization ensures that each installation perfectly matches its intended use case.

Sustainable and Environmental Benefits

Energy Efficiency Advantages

Modular clean panels contribute significantly to energy efficiency in controlled environments. Their superior insulation properties and tight seals help maintain stable temperatures and humidity levels while reducing the load on HVAC systems. This efficiency can lead to substantial energy savings over time, making them an environmentally responsible choice for modern facilities.

The panels' reflective properties can also enhance lighting efficiency within cleanroom spaces, reducing the need for artificial lighting and further decreasing energy consumption. These energy-saving features align with current sustainability initiatives while providing long-term operational cost benefits.

Material Sustainability and Recyclability

Modern modular clean panels are increasingly manufactured using sustainable materials and processes. Many manufacturers now offer panels made from recyclable materials or incorporate recycled content in their production. This focus on sustainability extends to the panels' entire lifecycle, from production through installation and eventual replacement.

The durability and longevity of modular clean panels also contribute to their environmental benefits by reducing the frequency of replacements and associated waste. When updates or modifications are needed, the modular nature of these panels often allows for partial replacement rather than complete system overhaul, further minimizing environmental impact.

Frequently Asked Questions About Modular Clean Panels

How long do modular clean panels typically last?

With proper maintenance and care, modular clean panels can maintain their performance characteristics for 15-20 years or more. Their durability and resistance to wear make them a long-term investment for facilities requiring controlled environments.

Can modular clean panels be installed in existing facilities?

Yes, modular clean panels are designed for both new construction and retrofit applications. Their flexible nature and standardized installation processes make them suitable for upgrading existing spaces to cleanroom standards with minimal disruption to ongoing operations.

What maintenance is required for modular clean panels?

Maintenance requirements are typically minimal, consisting primarily of regular cleaning with appropriate solutions and periodic inspection of seals and joints. The non-porous surfaces and sealed construction minimize the accumulation of contaminants and simplify the cleaning process.