Kritiškai svarbaus supratimas Švarus kambarys Standartai skirtingose pramonės šakose

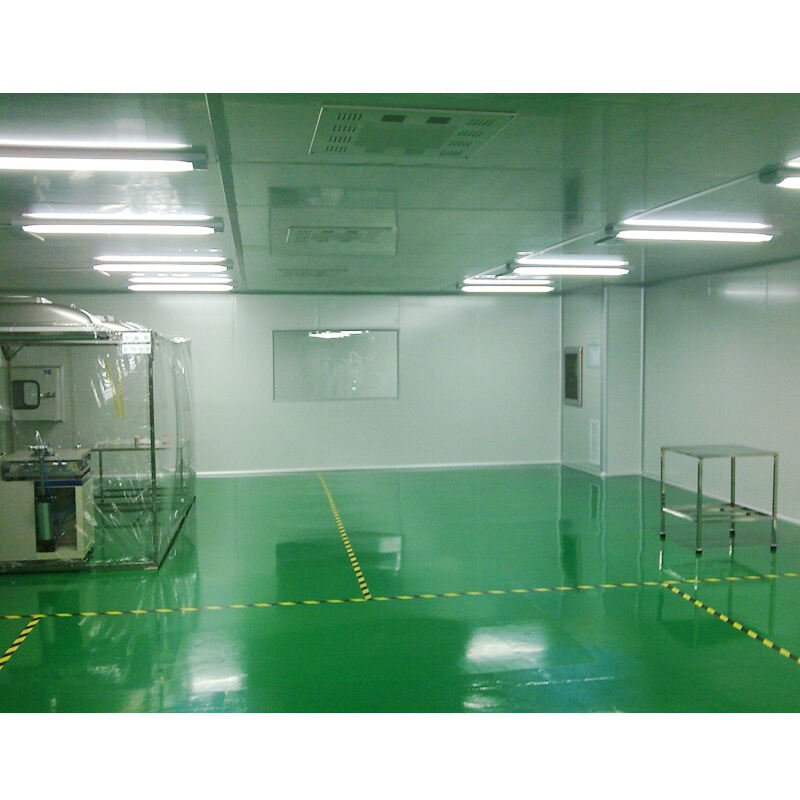

Valymo kambarių aplinka yra aukščiausio lygio užteršimo kontrolės pavyzdys, suteikiant griežtai reglamentuotą erdvę, kur oro dalelės, temperatūra, drėgmė ir kiti aplinkos veiksniai yra kruopščiai kontroliuojami. Šios specializuotos patalpos vaidina nepakeičiamą vaidmenį šiuolaikinoje gamyboje, moksliniuose tyrimuose ir plėtros procesuose įvairiose sektorių srityse. Įmonės visame pasaulyje reikšmingai investuoja į šių švarių aplinkų priežiūrą, kad būtų užtikrinta produkto kokybė, tyrimų patikimumas ir atitiktis reglamentams.

Valymo kambarių aplinkų įgyvendinimas skiriasi priklausomai nuo pramonės šakos, kiekviena sritis turi savų konkrečių reikalavimų ir standartų. Nuo griežčiausių ISO 1 klasės patalpų, naudojamų puslaidininkių gamyboje, iki ISO 8 klasės patalpų, tinkamų medicinos prietaisų surinkimui – šios kontroliuojamos aplinkos sudaro pagrindą kokybę kritiškai svarbiems procesams.

Puslaidininkių ir mikroelektronikos gamyba

Ultrašvarios gamybos reikalavimai

Puslaidininkių pramonė išlaiko vienas griežčiausių valymo patalpų bet kurioje pramonės šakoje. Šios patalpos dažniausiai veikia pagal ISO 1 arba 2 klasės standartus, kai net mikroskopinės dalelės gali padaryti visą mikroschemų partiją nevartotinę. Integrinių grandinių, mikroprocesorių ir kitų puslaidininkių komponentų gamybai reikia beveik visiškai be teršalų esančių aplinkų.

Šiuolaikinės puslaidininkių gamybos įmonės (fabrikai) naudoja sudėtingas oro apykaitos sistemas, specializuotus valymo protokolus ir griežtas apsauginių drabužių dėvėjimo procedūras. Darbuotojai privalo išlaikyti išsamų mokymą valymo patalpų protokolams ir dėvėti visą kūną dengiančius valymo patalpų drabužius, dažnai vadinamus triušių kostiumais, kad būtų išvengta žmogaus sukeltos užteršimo rizikos.

Pažengusios įrangos apsauga

Puslaidininkių gamyboje naudojama sudėtinga įranga reikalauja išskirtinio apsaugos nuo aplinkos taršos. Fotolitografijos mašinos, įranga gręžimui ir bandomiesiems prietaisams veikia su tikslumu, matuojamu nanometrais. Šios mašinos yra investicijos, vertos milijonų dolerių, todėl valymo kambarių aplinkos priežiūra tampa ne tik kokybės reikalavimu, bet ir svarbiu finansiniu reikalavimu.

Valymo kambarių aplinkos nuolatinis stebėjimas ir patvirtinimas užtikrina įrangos apsaugą ir veikimą. Pažengusios dalelių skaičiavimo sistemos ir aplinkos monitoriai suteikia realaus laiko duomenis apie oro kokybę, padedant išlaikyti ultrašvarias sąlygas, būtinas puslaidininkių gamybai.

Farmacijos gamyba ir tyrimai

Sterilių vaistų gamybos įrenginiai

Farmacijos pramonė labai pasikliauja švariosios patalpos aplinka, gaminant sterilias vaistines medžiagas, vakcinas ir biologinius produktus. Šios įmonės privalo atitikti griežtas Gerosios gamybos praktikos (GMP) taisykles ir paprastai užtikrinti ISO 5 klasės arba aukštesnės švaros lygmenį. Ypač injekcinių vaistų gamybai būtina aseptinės apdorojimo zonos su puikia kontaminacijos kontrolė.

Farmacijos gamybos švariosiose patalpose naudojamos specializuotos oro apykaitos sistemos su HEPA filtrais, slėgio kaskadomis ir nuolatine aplinkos stebėsena. Personalo rengimas aseptinėse technikose yra griežtai reglamentuotas, o darbuotojai privalo laikytis detalių drabužių dėvėjimo procedūrų, kad būtų išlaikyta sterilitybė.

Tyrimo ir plėtros laboratorijos

Farmacijos tyrimų įstaigos naudoja švarios patalpos aplinką vaistų kūrimui, stabilumo tyrimams ir kokybės kontrolės operacijoms. Šios kontroliuojamos erdvės užtikrina tyrimų duomenų vientisumą ir apsaugo jautrius biologinius medžiagas nuo užteršimo. Šiuolaikinius vaistų atradimo procesus dažnai apima darbas su ląstelių kultūromis, genetinėmis medžiagomis ir kitomis medžiagomis, kurios reikalauja nepriekaištingų aplinkos sąlygų.

Tyrimų švarios patalpos turi palaikyti nuolatinį temperatūros, drėgmės ir oro kokybės parametrus, tuo tarpu mokslininkai gali atlikti sudėtingus eksperimentus ir analizę. Šių įstaigų projektavimas dažnai apima specializuotą įrangą ir izoliavimo sistemas, kurios apsaugo tiek personalą, tiek tyrimų medžiagas.

Medicininės prietaisų gamyba

Kritinių komponentų surinkimas

Medicinos priemonių gamintojai naudoja valymo kambarių aplinką, kad užtikrintų savo produktų saugumą ir patikimumą. Nuodėm paprastų chirurginių įrankių iki sudėtingų įsodinamų įrenginių, surinkimo procesas turi vykti valdomomis sąlygomis, kad būtų užkirstas kelias užteršimui, kuris galėtų pakenkti pacientams. Tokios patalpos paprastai veikia ISO 7 arba 8 klasės lygiu, priklausomai nuo konkrečių įrenginių reikalavimų.

Komponentų, tokių kaip širdies stimuliatoriai, dirbtinės sąnariai ir diagnostikos įranga, surinkimas reikalauja kruopštaus dėmesio į aplinkos kontrolę. Darbuotojai laikosi griežtų protokolų dėl drabužių dėvėjimo, medžiagų perkėlimo ir valymo, kad būtų išlaikyti reikiami švaros standartai.

Sterilizavimo ir pakuotės operacijos

Švarios patalpos svarbios užbaigiant medicinos priemonių gamybą, ypač sterilizavimo ir pakuotės operacijų metu. Šios kontroliuojamos erdvės užtikrina, kad priemonės išliks sterilaus iki pat vartotojo. Pažengusios oro filtravimo sistemos, specializuotos pakuotės medžiagos ir patvirtintos valymo procedūros kartu veikia, kad būtų išlaikoma produkto vientisumas.

Reguliarios aplinkos stebėsena ir švarių patalpų sąlygų patvirtinimas padeda gamintojams atitikti reglamentinius reikalavimus ir užtikrinti nuoseklų produkto kokybę. Šių procesų dokumentacija sudaro esminę kokybės užtikrinimo programų dalį.

Biotecnologijos ir gyvosios gamtos mokslai

Ląstelių kultūros ir genų terapijos įrenginiai

Biotechnologijų pramonei reikia valymo patalpų įvairioms kritinėms operacijoms atlikti, įskaitant ląstelių kultūrą, genų terapijos gamybą ir audinių inžineriją. Šios patalpos turi išlaikyti puikios kokybės švaros standartus, kad būtų apsaugoti jautrūs biologiniai medžiagos ir užtikrinta tyrimų patikimumas. Daugeliui biotechnologijų taikymų reikia ISO 5 klasės ar geresnių sąlygų.

Šiuolaikinės biotechnologijų valymo patalpos apima sudėtingas aplinkos kontrolės sistemas, įskaitant tikslų temperatūros reguliavimą, drėgmės valdymą ir specializuotų oro apykaitos sistemas. Šioms patalpoms dažnai reikia papildomų izoliavimo priemonių, kad būtų apsaugoti darbuotojai nuo biologinių pavojų ir išlaikyta produkto steriliškumas.

Kokybės kontrolės laboratorijos

Biotechnologijos kokybės kontrolės operacijoms reikia kontroliuojamų aplinkų, kad būtų užtikrintas tikslus testavimas ir analizė. Švariosios patalpos palaiko įvairias analitines procedūras, nuo baltymų analizės iki genetinio testavimo. Šios patalpos turi išlaikyti stabilias sąlygas, kad būtų užtikrinti atkuriami rezultatai ir apsaugoma jautri testavimo įranga.

Laboratorinių švariųjų patalpų konstrukcija apima specializuotas darbo vietas, izoliavimo įrenginius ir aplinkos monitoringo sistemas. Reguliariai validuojant šias aplinkas palaikoma testavimo procedūrų vientisumą ir atitikimą reglamentinėms nuostatoms.

Aerospace Manufacturing

Satellite and Spacecraft Assembly

Aeronautikos pramonė naudoja švarius kambarius palydovų, kosminių laivų dalių ir jautrių elektroninių sistemų surinkimui ir bandymui. Šios patalpos paprastai palaiko ISO 7 klasės ar geresnes sąlygas, kad būtų apsaugota sudėtinga įranga nuo taršos, kuri gali sukelti gedimus kosmose. Aeronautikos srityje rizika ypač didelė, nes po paleidimo įrangoje dažnai neįmanoma atlikti remonto darbų.

Švariųjų patalpų protokolai aeronautikos gamyboje apima specialius valymo procesus, dalelių stebėseną ir griežtą medžiagų kontrolę. Darbuotojai privalo laikytis detalių procedūrų, susijusių su komponentų tvarkymu ir aplinkos vientisumo palaikymu.

Tikslinių optikos gamyba

Aerospace technologijų tikslaus optinio komponentų gamybai reikia išskirtinai švarių aplinkų. Teleskopai, jutikliai ir ryšių įranga priklauso nuo švarių optinių paviršių, kuriuos gali sugadinti net menkiausias užteršimas. Švarios patalpos apsaugo šiuos jautrius komponentus gamybos ir surinkimo metu.

Pažengusios filtravimo sistemos ir specialūs valymo protokolai padeda išlaikyti būtinąsias aplinkos sąlygas. Reguliarios bandymų ir patvirtinimų procedūros užtikrina, kad optiniai komponentai atitiktų aukštuosius reikalavimus, keliamus aerospace pritaikymams.

Dažniausiai užduodami klausimai

Kas nulemia švarios patalpos klasifikavimą?

Valymo kambarių klasifikacija nustatoma pagal maksimalų leistiną dalelių tam tikro dydžio skaičių kubiniame ore. ISO 14644-1 standartas apibrėžia devynias klases, nuo ISO klasės 1 (griežčiausios) iki ISO klasės 9 (palankiausios). Bendrą klasifikaciją daro įtaką ir tokie veiksniai kaip oro srauto greitis, filtravimo našumas ir slėgio skirtumai.

Kaip palaikomi ir stebimi valymo kambarių aplinkos parametrai?

Valymo kambarių aplinka palaikoma naudojant sudėtingas oro apykaitos sistemas, HEPA filtrus, slėgio kaskadus ir reguliarius valymo protokolus. Tolydžio veikiančios stebėjimo sistemos seka dalelių skaičių, temperatūrą, drėgmę ir slėgio skirtumus. Reguliarios patikros ir sertifikavimas užtikrina atitikimą reikiamais standartais, o personalo mokymai ir griežti darbo reikalavimai padeda išlaikyti reikiamą švaros lygį.

Kokią asmeninę apsaugos įrangą reikia naudoti valymo kambariuose?

Asmeninio apsaugos priemonių reikalavimai skiriasi priklausomai nuo valymo kambario klasės ir paskirties, tačiau paprastai apima valymo kambario kostiumus (kiškių kostiumus), batus, pirštines, kaukes ir plaukų gaubtus. Griežtesnėse aplinkose gali prireikti kelių apsaugos sluoksnių ir specialių apsirengimo procedūrų. Visa asmeninė apsauga turi būti suderinama su valymo kambariu ir keičiama pagal nustatytas procedūras.