Modern industrial facilities and commercial buildings face increasingly complex air quality challenges that require sophisticated yet adaptable solutions. Traditional HVAC systems often fall short when facilities need to expand, modify operations, or implement specialized environmental controls. This is where modular air handling units emerge as game-changing technology, offering unprecedented flexibility and efficiency in air treatment applications across diverse industries including pharmaceuticals, food processing, cleanrooms, and manufacturing facilities.

Enhanced Flexibility and Scalability

Adaptable Configuration Options

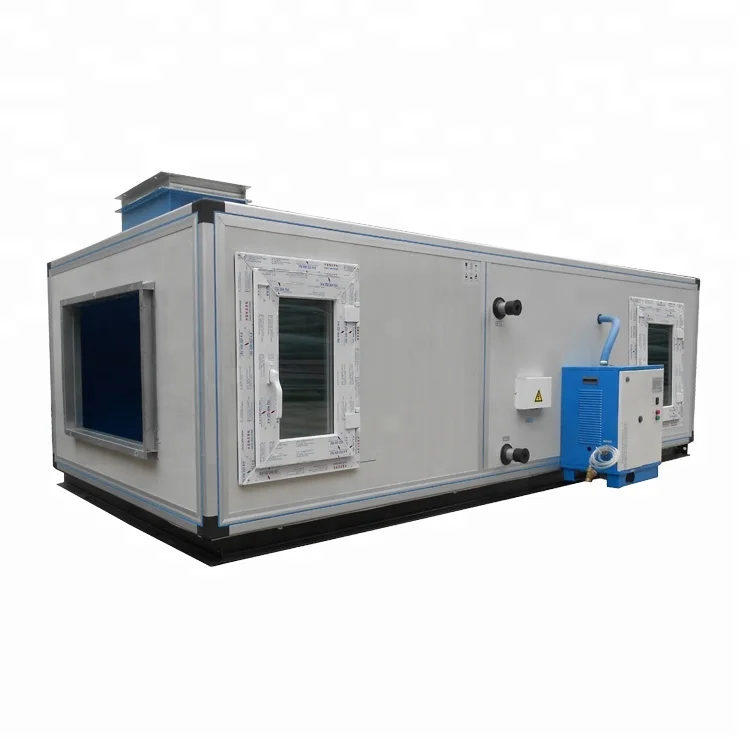

Modular air handling units revolutionize facility planning by offering unmatched configurability that traditional systems simply cannot match. These systems consist of individual modules that can be combined, rearranged, or expanded based on specific operational requirements. Engineers can select from various module types including filtration units, heating coils, cooling coils, humidification sections, and heat recovery components to create customized solutions. This modular approach eliminates the constraints of pre-engineered systems and allows facilities to achieve precise environmental control tailored to their unique processes.

The scalability advantage becomes particularly evident when facilities undergo expansion or process modifications. Rather than replacing entire air handling systems, operators can simply add or reconfigure modules to accommodate new requirements. This approach significantly reduces capital expenditure while maintaining optimal performance standards. Manufacturing facilities experiencing seasonal production variations benefit enormously from this flexibility, as they can adjust their air handling capacity without investing in oversized equipment that operates inefficiently during low-demand periods.

Future-Proof Investment Strategy

Investment in modular air handling units represents a strategic approach to long-term facility management that protects against technological obsolescence. As industry standards evolve and new regulations emerge, modular systems can be updated incrementally rather than requiring complete replacement. This future-proofing capability proves especially valuable in highly regulated industries where compliance requirements frequently change. Pharmaceutical facilities, for instance, can upgrade filtration modules to meet new sterile processing standards without disrupting entire production lines.

The modular design philosophy also accommodates emerging technologies such as advanced sensors, IoT connectivity, and artificial intelligence integration. Facility managers can incorporate these innovations as they become available and cost-effective, ensuring their air handling systems remain at the forefront of efficiency and control capabilities. This evolutionary upgrade path contrasts sharply with traditional systems that become stranded assets when new technologies emerge.

Operational Efficiency and Energy Performance

Optimized Energy Consumption

Energy efficiency stands as one of the most compelling advantages of modular air handling units, particularly in an era of rising energy costs and environmental consciousness. These systems excel at matching energy consumption to actual demand through precise zone control and variable capacity operation. Unlike oversized traditional units that cycle on and off inefficiently, modular systems can operate specific modules only when and where needed, resulting in substantial energy savings across various load conditions.

Advanced control systems integrated with modular air handling units enable sophisticated energy management strategies including demand-controlled ventilation, heat recovery optimization, and predictive load management. These intelligent systems continuously monitor environmental conditions, occupancy patterns, and equipment performance to minimize energy waste while maintaining optimal indoor air quality. The cumulative effect of these efficiency measures can reduce HVAC energy consumption by 20-40% compared to conventional systems, translating to significant operational cost savings over the equipment lifecycle.

Reduced Maintenance Requirements

Maintenance efficiency represents another critical advantage of modular air handling units that directly impacts operational costs and system reliability. The modular design allows maintenance technicians to service individual components without shutting down entire systems, minimizing downtime and production disruptions. This component-level accessibility proves particularly valuable in mission-critical applications where continuous operation is essential for product quality or safety compliance.

Standardized module designs also streamline maintenance procedures and spare parts inventory management. Technicians become highly proficient with common module types, reducing service time and the likelihood of errors. Facilities can maintain smaller spare parts inventories since modules are interchangeable across different system configurations. This standardization extends to diagnostic procedures and troubleshooting protocols, enabling faster problem resolution and more predictable maintenance scheduling.

Installation and Space Optimization

Streamlined Installation Process

The installation advantages of modular air handling units extend far beyond simple convenience, offering substantial cost and time savings that impact project timelines and budgets. Factory pre-fabricated modules arrive on-site fully assembled, tested, and ready for integration, eliminating much of the field construction work required for traditional built-up systems. This pre-fabrication approach ensures consistent quality control and reduces the risk of installation errors that could compromise system performance or require costly corrections.

Construction schedules benefit significantly from modular installation methods, as mechanical contractors can complete air handling system installation while other trades continue their work in parallel. The reduced installation time minimizes disruption to existing operations in retrofit applications and accelerates occupancy schedules for new construction projects. Additionally, the cleaner installation process generates less construction debris and requires fewer specialized tools and equipment on-site.

Space Utilization Efficiency

Space constraints in modern facilities make efficient equipment layouts increasingly critical, and modular air handling units excel in optimizing available space through flexible configuration options. These systems can be arranged in various configurations including stacked arrangements, distributed layouts, or compact footprints that maximize the use of available mechanical room space. The ability to separate different functional modules allows designers to position components optimally for maintenance access, airflow patterns, and integration with existing building systems.

Vertical stacking capabilities prove particularly valuable in urban facilities where floor space commands premium pricing. Modular units can be configured to utilize vertical space efficiently while maintaining accessibility for service and component replacement. This three-dimensional design flexibility contrasts with traditional horizontal air handlers that consume large areas of valuable floor space and may require extensive ductwork to reach all served zones.

Quality Control and Performance Standards

Consistent Manufacturing Quality

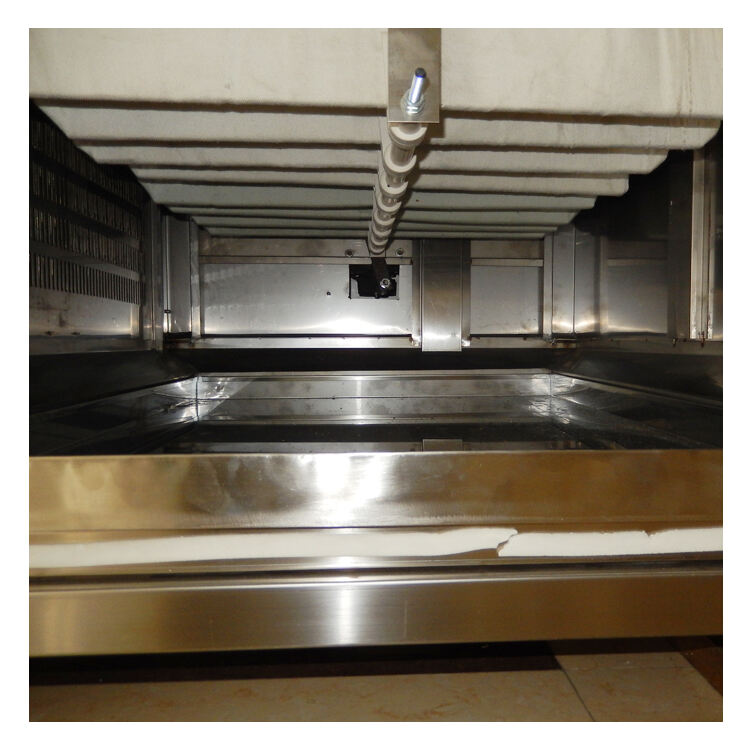

Factory manufacturing of modular air handling units ensures consistent quality standards that field-assembled systems struggle to match. Controlled manufacturing environments enable precise assembly procedures, comprehensive testing protocols, and quality assurance measures that guarantee each module meets specified performance criteria before shipment. This factory quality control extends to welding, insulation installation, component alignment, and finish quality, resulting in systems that deliver reliable long-term performance.

Advanced manufacturing techniques employed in modular production include computer-controlled cutting and forming equipment, automated assembly processes, and integrated testing systems that verify performance parameters under controlled conditions. These capabilities ensure dimensional accuracy, proper sealing, and optimal component integration that directly translate to superior field performance. The controlled manufacturing environment also enables strict adherence to industry standards and certification requirements that may be difficult to achieve through field construction methods.

Performance Verification and Testing

Comprehensive testing protocols implemented during modular air handling unit manufacturing provide verified performance data that specifiers and operators can rely on with confidence. Factory testing includes airflow verification, pressure drop measurements, thermal performance validation, and acoustic testing under controlled conditions that replicate actual operating scenarios. This testing data enables accurate system modeling and performance prediction that supports optimal system design and operation.

Field commissioning of modular systems benefits from pre-verified module performance, reducing the time and complexity required to achieve optimal system operation. Commissioning agents can focus on system integration and control optimization rather than troubleshooting basic component performance issues. This streamlined commissioning process reduces project costs and accelerates the transition to full operational status, allowing facilities to realize the benefits of their air handling investment more quickly.

Cost-Effectiveness and Return on Investment

Reduced Total Cost of Ownership

The financial advantages of modular air handling units extend well beyond initial purchase price to encompass total cost of ownership considerations that significantly impact long-term facility operating budgets. Reduced installation costs, lower energy consumption, simplified maintenance procedures, and extended equipment life all contribute to superior return on investment compared to traditional air handling approaches. These economic benefits become more pronounced over the typical 15-20 year equipment lifecycle, often justifying higher initial investment through accumulated operational savings.

Energy cost savings alone can justify modular air handling unit selection in many applications, particularly facilities with high ventilation requirements or extended operating hours. The precise control capabilities and optimized component selection available through modular design enable energy performance that conventional systems cannot match. Additionally, utility rebate programs often favor high-efficiency modular systems, providing additional financial incentives that improve project economics.

Value Engineering Opportunities

Modular air handling units enable sophisticated value engineering approaches that optimize performance while controlling costs through strategic component selection and system configuration. Design teams can evaluate different module combinations to identify the most cost-effective solution for specific performance requirements, often discovering configurations that exceed performance targets while reducing overall system cost. This optimization process benefits from the extensive performance data available for standardized modules.

The ability to phase system installation and expansion provides additional value engineering opportunities by allowing facilities to invest incrementally as requirements develop or budgets allow. Initial installations can focus on essential capacity with provision for future expansion, spreading capital investment over multiple budget cycles while maintaining system compatibility and performance standards. This phased approach proves particularly valuable for growing businesses or facilities with uncertain future requirements.

FAQ

What industries benefit most from modular air handling units

Modular air handling units provide exceptional value across numerous industries, with particular advantages in pharmaceuticals, biotechnology, food processing, electronics manufacturing, and healthcare facilities. These industries benefit from the precise environmental control, easy expansion capability, and simplified maintenance that modular systems provide. Cleanroom applications especially favor modular units due to their ability to maintain strict contamination control while accommodating process changes. Data centers and critical facilities also benefit from the redundancy and serviceability advantages of modular designs.

How do modular air handling units compare in terms of initial cost

While modular air handling units may have higher initial purchase costs compared to basic traditional systems, they typically provide superior value when considering total project costs including installation, commissioning, and early operational phases. The factory fabrication and pre-testing of modular units often reduces installation time and costs significantly, while the simplified commissioning process minimizes startup expenses. Additionally, the long-term operational savings and flexibility benefits usually provide positive return on investment within the first few years of operation.

Can existing facilities retrofit modular air handling units

Retrofit applications represent an ideal use case for modular air handling units due to their flexible configuration options and streamlined installation requirements. The ability to size modules precisely for existing space constraints and mechanical room layouts makes retrofits more feasible than with traditional built-up systems. Additionally, the reduced installation time minimizes disruption to ongoing facility operations, which proves crucial in production environments where downtime costs can be substantial. Many facilities successfully phase retrofit installations to further minimize operational impact.

What maintenance advantages do modular systems provide

Modular air handling units offer significant maintenance advantages through improved accessibility, standardized components, and the ability to service individual modules without system shutdown. Maintenance technicians can quickly become proficient with standard module designs, reducing service time and improving reliability. The ability to maintain spare modules for critical applications enables rapid component replacement with minimal downtime. Additionally, the factory assembly and testing of modules ensures consistent quality that reduces unexpected maintenance requirements and extends overall system life.