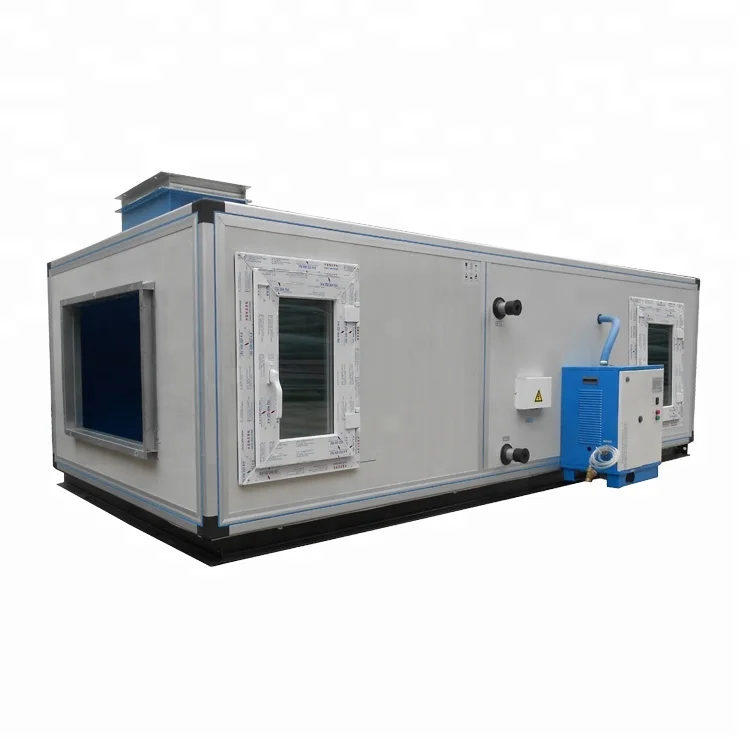

Air handling units serve as the backbone of modern HVAC systems, managing air circulation, filtration, and conditioning in commercial and industrial facilities. These sophisticated systems ensure optimal indoor air quality while maintaining energy efficiency across diverse applications. However, like any complex mechanical system, they encounter various operational challenges that can impact performance and reliability. Understanding these common issues and their corresponding solutions is crucial for facility managers, maintenance teams, and engineers who depend on consistent air handling performance.

Filter-Related Problems and Maintenance Solutions

Clogged and Dirty Filters

Filter contamination represents one of the most frequent issues affecting air handling units, leading to reduced airflow and compromised system efficiency. When filters become saturated with dust, pollen, and other airborne particles, they create significant resistance that forces the system to work harder. This increased workload not only elevates energy consumption but also places additional strain on fans and motors, potentially shortening their operational lifespan.

Regular filter inspection and replacement schedules form the foundation of effective preventive maintenance. High-efficiency particulate air filters should be monitored using differential pressure gauges to determine optimal replacement timing. Implementing automated monitoring systems can alert maintenance teams when pressure differentials exceed predetermined thresholds, ensuring timely filter changes before performance degradation occurs.

Incorrect Filter Selection and Installation

Selecting inappropriate filter types or installing them incorrectly can severely compromise system performance and air quality. Filters with excessive resistance may reduce airflow beyond design parameters, while inadequate filtration allows contaminants to bypass the system entirely. Proper filter sizing ensures optimal fit within housing frames, preventing air leakage around filter edges that undermines filtration effectiveness.

Professional assessment of filtration requirements should consider specific application needs, including particle size distribution, contaminant types, and required air quality standards. Installing filters according to manufacturer specifications and airflow direction markings prevents common installation errors that reduce system efficiency and effectiveness.

Mechanical Component Failures and Repair Strategies

Fan and Motor Malfunctions

Fan assemblies and drive motors represent critical components whose failure can completely shut down air handling operations. Common issues include bearing wear, belt slippage, motor overheating, and blade damage from debris or imbalanced rotation. These problems often develop gradually, manifesting as unusual noises, vibrations, or reduced airflow before complete failure occurs.

Implementing vibration analysis and thermal monitoring programs enables early detection of developing mechanical issues. Regular lubrication of bearing assemblies, belt tension adjustments, and motor electrical connection inspections help prevent premature component failure. Maintaining spare parts inventory for critical components ensures rapid restoration of service when replacements become necessary.

Damper Control and Actuator Problems

Damper systems control airflow distribution and mixing within air handling units, but actuator failures and mechanical binding can disrupt proper operation. Pneumatic and electric actuators may experience seal failures, motor burnout, or calibration drift that prevents accurate damper positioning. Mechanical linkages can bind due to corrosion, debris accumulation, or structural misalignment.

Regular actuator calibration and linkage lubrication maintain smooth damper operation and accurate control response. Implementing feedback sensors provides real-time position verification, enabling early detection of control discrepancies. Scheduled inspection of pneumatic supply systems ensures adequate pressure and clean air delivery to pneumatic actuators.

Coil Performance Issues and Optimization Methods

Heating and Cooling Coil Degradation

Heat exchanger coils experience gradual performance degradation due to fouling, corrosion, and fin damage that reduces thermal transfer efficiency. Dirt accumulation on coil surfaces creates insulating layers that impede heat transfer, while corrosion can lead to refrigerant or water leaks. Damaged fins restrict airflow and create turbulence that further reduces system efficiency.

Professional coil cleaning using appropriate chemical solutions and pressure washing techniques restores thermal performance and extends coil life. Implementing water treatment programs for hydronic systems prevents scale formation and corrosion that degrades coil integrity. Regular inspection of coil fins and prompt repair of damaged sections maintains optimal airflow characteristics.

Condensate Drainage and Water Management

Cooling coil condensate removal systems frequently experience blockages and drainage problems that can cause water damage and microbial growth. Clogged drain pans and pipes create standing water conditions that promote bacteria and mold development, potentially compromising indoor air quality. Inadequate drainage slope or undersized drain systems may cause overflow conditions during peak cooling loads.

Installing drain pan treatments and implementing regular cleaning schedules prevent microbial growth and maintain proper drainage flow. Verifying drain system capacity and slope ensures adequate water removal under all operating conditions. Emergency overflow sensors and alarms provide early warning of drainage system failures before water damage occurs.

Control System Troubleshooting and Calibration

Sensor Accuracy and Calibration Drift

Temperature, humidity, and pressure sensors throughout air handling systems gradually lose calibration accuracy over time, leading to improper control responses and energy waste. Drift in sensor readings can cause unnecessary heating or cooling, excessive fan operation, or inadequate ventilation that fails to meet occupancy requirements. Sensor contamination and physical damage further compromise measurement accuracy.

Establishing regular sensor calibration schedules using certified reference instruments maintains control system accuracy and optimal performance. Implementing redundant sensors for critical measurements provides backup capability and enables cross-checking of primary sensor readings. Protecting sensors from physical damage and environmental contamination extends their operational life and reliability.

Control Logic and Programming Issues

Building automation systems managing air handling units may develop programming errors, communication failures, or logic conflicts that disrupt normal operation. Incorrect control sequences can cause equipment cycling, energy waste, or failure to maintain desired environmental conditions. Network communication problems prevent proper coordination between system components and central control interfaces.

Regular review and testing of control sequences ensures proper system operation under various load conditions and operating modes. Implementing network monitoring tools identifies communication issues before they impact system performance. Maintaining current backup copies of control programs enables rapid restoration of proper operation following system failures or modifications.

Energy Efficiency Optimization and Performance Enhancement

Variable Frequency Drive Integration

Traditional constant-speed fan operations consume excessive energy during periods of reduced air handling requirements, representing significant opportunities for efficiency improvements. Variable frequency drives enable fan speed modulation based on actual system demands, reducing energy consumption while maintaining adequate air delivery. Proper VFD sizing and programming optimize energy savings while preventing motor overheating and mechanical stress.

Implementing demand-controlled ventilation strategies using occupancy sensors and air quality monitors maximizes energy savings while ensuring adequate indoor air quality. Regular VFD parameter optimization based on actual system performance data fine-tunes energy efficiency and extends equipment life. Monitoring power consumption and system performance metrics quantifies energy savings and identifies opportunities for further optimization.

Heat Recovery and Energy Conservation

Air handling systems without heat recovery capabilities waste significant amounts of conditioned air energy, particularly in facilities with high ventilation requirements. Installing heat recovery wheels, plate heat exchangers, or run-around coil systems captures waste energy from exhaust airstreams to precondition incoming fresh air. Proper heat recovery system sizing and maintenance maximizes energy transfer efficiency while preventing cross-contamination between airstreams.

Regular heat exchanger cleaning and inspection maintains thermal transfer efficiency and prevents fouling that reduces energy recovery performance. Implementing bypass dampers enables system operation during maintenance periods and prevents freeze damage in cold climates. Monitoring heat recovery effectiveness and energy savings quantifies system benefits and justifies ongoing maintenance investments.

Preventive Maintenance Programs and Best Practices

Scheduled Inspection and Maintenance Protocols

Comprehensive preventive maintenance programs significantly reduce unexpected failures and extend air handling unit service life through systematic inspection and component care. Developing maintenance schedules based on manufacturer recommendations, operating hours, and environmental conditions ensures appropriate service intervals for all system components. Documentation of maintenance activities and component conditions enables trend analysis and predictive maintenance planning.

Training maintenance personnel on proper inspection techniques and safety procedures ensures consistent service quality and worker protection. Implementing computerized maintenance management systems streamlines scheduling, work order generation, and parts inventory management. Regular performance testing and efficiency measurements quantify maintenance effectiveness and identify areas requiring additional attention.

Condition Monitoring and Predictive Analytics

Advanced condition monitoring technologies enable early detection of developing problems before they cause system failures or performance degradation. Vibration analysis, thermal imaging, and electrical signature analysis identify mechanical issues, electrical problems, and efficiency losses in their early stages. Implementing Internet of Things sensors and analytics platforms provides continuous monitoring capability and automated alert generation.

Establishing baseline performance parameters enables comparison with current operating conditions to identify gradual degradation trends. Regular analysis of energy consumption patterns, runtime hours, and maintenance histories reveals optimization opportunities and component replacement needs. Predictive maintenance strategies based on actual component condition rather than fixed schedules maximize equipment reliability while minimizing maintenance costs.

FAQ

What are the most common signs that an air handling unit needs immediate attention

The most obvious indicators include unusual noises such as grinding, squealing, or rattling sounds that suggest mechanical problems with fans, motors, or bearings. Reduced airflow throughout the building, inconsistent temperature control, and increased energy consumption often signal filter blockages, coil fouling, or control system malfunctions. Visible water leaks, unusual odors, or excessive humidity levels require immediate investigation to prevent water damage and indoor air quality problems.

How often should air handling unit filters be replaced or cleaned

Filter replacement frequency depends on environmental conditions, system usage, and filter type, but most commercial installations require monthly to quarterly changes. Monitoring differential pressure across filter banks provides the most accurate replacement timing, with replacement typically needed when pressure drop exceeds manufacturer specifications. High-contamination environments such as manufacturing facilities may require more frequent filter changes, while clean office environments may extend replacement intervals.

What energy efficiency improvements can be made to existing air handling systems

Installing variable frequency drives on fan motors provides immediate energy savings by matching fan speed to actual air delivery requirements. Adding heat recovery systems captures waste energy from exhaust air to precondition incoming fresh air, significantly reducing heating and cooling loads. Upgrading to high-efficiency motors, implementing demand-controlled ventilation based on occupancy, and optimizing control sequences can achieve substantial energy reductions while improving comfort and air quality.

When should an air handling unit be replaced rather than repaired

Replacement becomes economically justified when repair costs exceed 50-60% of replacement value, or when the unit consistently fails to meet performance requirements despite proper maintenance. Units over 15-20 years old may lack energy efficiency features available in modern equipment, making replacement cost-effective through energy savings. Obsolete control systems, discontinued parts availability, and inability to meet current building codes or air quality standards also indicate replacement needs.

Table of Contents

- Filter-Related Problems and Maintenance Solutions

- Mechanical Component Failures and Repair Strategies

- Coil Performance Issues and Optimization Methods

- Control System Troubleshooting and Calibration

- Energy Efficiency Optimization and Performance Enhancement

- Preventive Maintenance Programs and Best Practices

- FAQ